FAQ-Fire Attack Questions: Part 2

April 20th, 2013

Captain Mike Sullivan with the Mississauga Ontario Fire Department and I are continuing our dialog with another series of questions related to the science behind fire attack and fire control methods. Mike’s next several question deal with gas and surface cooling.

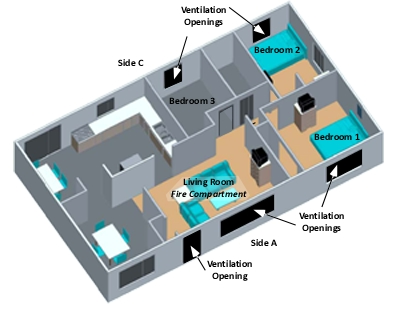

I know the best way to extinguish a fire is to put water on it but my questions below deal with a situation of large, open concept homes where you can see the entire main floor except the kitchen cooking area, in many cases this area is not separate from the open floor plan but around the corner so we can’t hit the fire until we get around that corner. My questions are all geared around how to cool the environment as you make your way to the fire (if you need to go to the very back of the house to get to the fire, fire can’t be seen).

When you answered the question about the effects of flowing a straight/solid stream across the ceiling it sounds as if this is really only surface cooling and not effectively gas cooling. If this is true then I was wondering what the value of doing this is, what are the main benefits of cooling the ceiling, walls and floor (and any furniture etc. the water lands on)? Also, what do you recommend to those departments that only use solid bore nozzles?

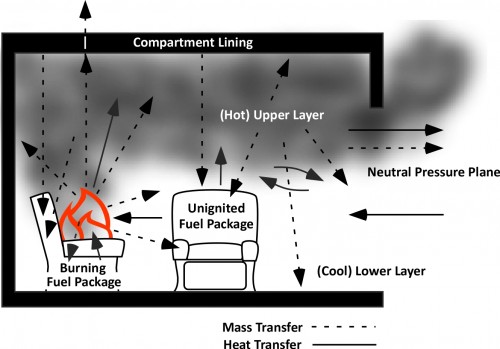

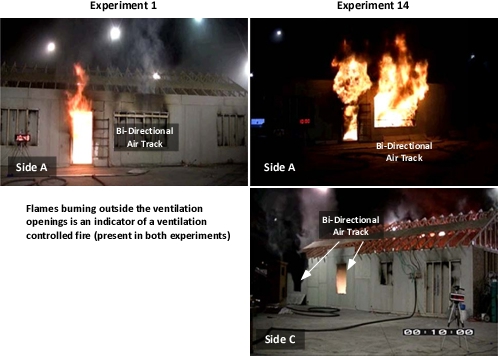

Use of a solid (or straight) stream off the ceiling has some effect on cooling the gases, but this is limited as the droplets produced are quite large and do not readily vaporize in the hot upper layer (great for direct attack, but not so much for gas cooling). The value of doing this is that any energy taken out of the hot upper layer (buy cooling the gases or by cooling surfaces and subsequent transfer of energy from hot gases to the cooler surfaces) will have some positive effect. In addition, hot combustible surfaces, depending on temperature are likely pyrolizing and adding hot, gas phase fuel to the upper layer. Cooling reduces pyrolysis and the fuel content of the smoke overhead.

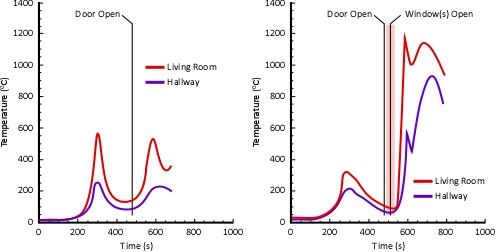

The following video of the “Nozzle Forward”, Aaron Fields, Seattle Fire Department demonstrates some excellent hose handling techniques and also provides an illustration of how a solid stream nozzle can be used to cool hot gases by breaking up the stream on contact with compartment linings. Have a look at the video between 2:00 and 2:30 where the nozzle is being rotated as in a combination attack while advancing down a hallway. Note that the stream breaks up on contact with the ceiling and walls, providing a distribution of large droplets in the overhead area.

This technique can be quite effective when faced with a large volume of fire and ventilation is provided in front of the fire attack. However, if the hallway is not involved in fire, but there is a hot layer of smoke overhead, this approach is less effective as large droplets are less efficient in cooling the hot gases and much of the water will end up on the floor, not having done appreciable work.

While this will likely generate some hate and discontent, I would recommend that departments using only solid stream nozzles reconsider their choice. This type of nozzle has a number of great characteristics, but also has a number of significant limitations, principal among which is limited ability to cool the hot upper layer when dealing with shielded fires. That said, the firefighter riding backwards or company officer in the right front seat may have limited impact on this decision (at least in the short term). If all you have to work with is a solid stream nozzle, directing the stream off the ceiling to break up the pattern and provide limited gas cooling when dealing with extremely hot gases overhead are likely a reasonable option.

I understand how penciling a fog stream in the hot gas layer is the best way to cool the gases. My concern is this, where I work there are many new homes with open concept, large rooms and little compartmentation. I like the idea of cooling the gases above my head but I still have a large room full of gases that could still flash. Sure I’m cooling the gases around me but if the gases at the other end of the open space flash, I am still in the same room and in trouble. I would prefer to cool that area before I get there. What are your recommendations for this situation?

As a point of clarification, we use the term “penciling” in reference to an intermittent straight stream application. Gas cooling is most effectively accomplished with pulsed or intermittent application of water fog. We refer to this technique as “pulses” (to differentiate this from penciling with a straight or solid stream)

We also have quite a few large residential occupancies with open floor plans. The issue of large area or volume compartments also applies in commercial and industrial building as well. Gas cooling simply provides a buffer zone around the hose team, but other than in a small compartment does not change conditions in the upper layer throughout the space. Gas cooling must be a continuous process while progressing towards a shielded fire. The upper limit of area (or more appropriately volume) is an unanswered question. My friend Paul Grimwood, Principal Fire Safety Engineer with the Kent Fire and Rescue Service in the UK holds that the upper limit with a relatively normal ceiling height is approximately 70 m2 (753 ft2). Paul’s perspective is anecdotal and not based on specific scientific research. However, this is not unreasonable, given the reach of a narrow fog pattern and vaporization of water as it passes through the upper layer. Given the higher flow rates used by the North American fire service, it may be possible to control a somewhat larger area than Paul suggests, but this remains to be determined.

As to an answer to this problem, pulsed application does not always mean short pulses, multiple long pulses with a narrow pattern or a sweeping long pulse may be used to cover a larger area. In addition, large area compartments or open floor plan spaces may require multiple lines to adequately control the environment. The purpose of the backup line is to protect the means of egress for the attack line and this is of paramount importance in an open plan building.

The following two videos demonstrate the difference between short and long pulses. At 115 lpm (30 gpm) the flow rates in these two videos are low by North American standards, but are fairly typical for gas cooling applications in many parts of the world. Short pulses can be used effectively up to approximately 570 lpm (150 gpm) with minimal water hammer, for higher flow rates, long pulses are more appropriate.

When we do these quick bursts of fog to cool the gases we are not using much water compared to the feeling that the best way to handle this is to flow a large amount of water and basically soak the entire area down before you advance through it. I was hoping you could comment on this.

As noted in the answer to your previous question, pulses are sometimes, but not always quick. In a typical legacy residence (small compartments) short pulses are generally adequate to cool hot gases overhead. When accessing a shielded fire, and cooling the hot gases overhead it is not generally necessary to cool hot surfaces and fuel packages such as furniture (it may be a different story in the fire compartment). Water remaining on the floor or soaked into contents did not do significant work and simply added to fire control damage. We should not hesitate to use an adequate amount of water for fear of water damage, but tactical operations should focus on protecting property once (or while) we are acting to ensure the safety of occupants and firefighters.

We often enter house fires where the house is full of smoke but the smoke is not necessarily very hot. In these cases we would not normally cool the gases. From what we understand now, smoke is fuel and with open concept homes this smoke could ignite close to the fire therefore igniting the smoke nearer to us. What I was wondering is what are you teaching in regards to cooling the smoke, do you do it only when you feel a lot of heat or start cooling regardless?

As the temperature of the upper layer drops, the effectiveness of application of pulsed water fog diminishes. That said, if the upper layer is hot enough to vaporize some of the water (i.e. above 100o C), application of water will further cool the gases and provide some thermal ballast (the water will have to be heated along with the gases for ignition to occur).

When presented with cold (< 100o C) smoke, firefighters still face a hazard as gas phase fuel can still be ignited resulting in a flash fire (if relatively unconfined) or smoke explosion. The only real solution to this hazard is to create a safe zone by removing the smoke through tactical ventilation.

Mike and I will continue this dialog next week with a discussion of the protective capabilities of fog streams.