Understanding Flashover:

Myths and Misconceptions

Thursday, July 30th, 2009

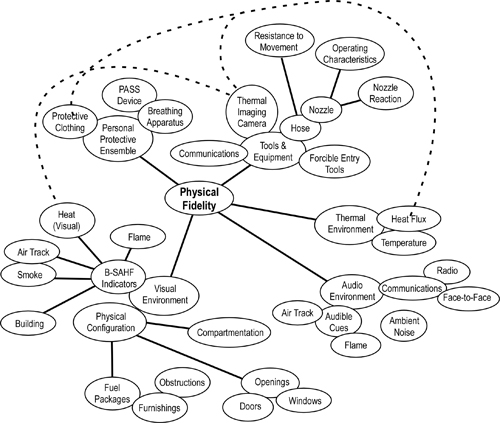

Flashover is likely the most common type of extreme fire behavior encountered in structural firefighting. As my friends and colleagues from Sweden frequently observe, this is not really extreme fire behavior, its normal fire behavior. I think it is both. The term extreme “is framed within the context of our perception with ‘extreme’ defining our limited ability to control it and its potential impact on firefighter safety” (Close, 2005). However, occurrence of flashover is not abnormal or random; it is a simple matter of the chemistry and physics involved in a compartment fire.

Misconceptions

For some time, I have been collecting comments and statements related to extreme fire behavior phenomena in the press, fire service publications, and training materials. While it is quite possible to find accurate information on the phenomena of flashover, misconceptions and erroneous information are also common.

- There may have been a flashover at the home when gas in the air ignited

- Firefighters who responded to the blaze nearly got caught inside when an explosion or dangerous condition called a “flashover” occurred

- A flashover occurs when the air temperature reaches between 900 and 1,000, which is hot enough to ignite any gases that are in the air… The result is potentially deadly explosive conditions

- It’s what we call a flashover, were you have a combustible gas or even dust in the area and then all of a sudden, almost explosive-like, that vapour cloud will ignite

- Firefighters were caught in a rare “flashover,” an instance in which superheated gases and combustible materials simultaneously ignite

- When the room bursts into flame, flashover has occurred

Each of the preceding statements was made (or at least reported to have been made) by experienced fire officers. Failure to recognize and mitigate conditions that may result in flashover during firefighting operations results in significant risk to firefighters. At the core of recognition and mitigation is understanding what flashover is, what causes it, and the conditions necessary for it to occur.

What is Flashover?

Flashover is the sudden transition to fully developed fire. This phenomenon involves a rapid transition to a state of total surface involvement of all combustible material within the compartment. If flashover occurs, the rate of heat release in the compartment as well as the temperature in the compartment increases rapidly. Flashover may occur as the fire develops in a compartment or additional air is provided to a ventilation-controlled fire (that has insufficient fuel in the gas phase and/or temperature to backdraft).

Indicators of flashover include a radiant heat flux at the floor of 15-20 kW/m2 (radiant heat transfer sufficient to quickly raise ordinary combustibles to their ignition temperature) and average upper layer temperature of 500o-600o C (932o-1112o F) (Drysdale, 1998). More observable indicators include rapid flame spread and extension of flames out of compartment openings. Compartment windows may also fail due to rapid temperature increases on the inner surface of window glazing (Gorbett & Hopkins (2007).

Figure 1.Flashover

Note: Photo by William Cobb, Cornelius – Lemley Fire Rescue

Flashover and Fire Development

There are a number of definitions or ways to describe flashover, but most importantly, it is a rapid transition to a fully developed fire.

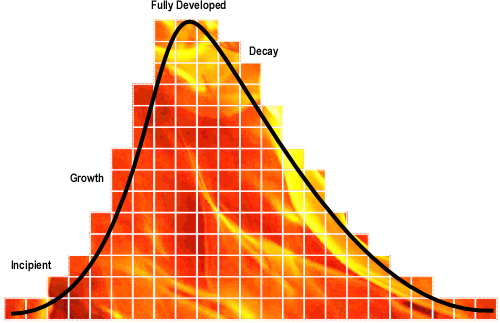

A fuel package such as a couch or upholstered chair burning in open air progresses through four phases. In the incipient stage the fire involves only a small amount of fuel, as the fire moves into the growth stage, more fuel becomes involved and the speed of the combustion reaction increases. Eventually the entire object becomes involved and the fire is fully developed. As the fuel is consumed the fire begins to decay. Throughout this process, fire development is fuel controlled; the speed of fire development and energy released is dependent on the characteristics and configuration of the fuel. As combustion is taking place in the open, there is adequate oxygen to support combustion as the fire progresses through each of the four stages.

Heat of combustion is the energy released when a specific mass of fuel is completely burned. The total energy released when an object burns is dependent on the heat of combustion and the amount (mass) of fuel burned. Heat of combustion is measured in Joules (J). However, this only provides part of the picture. Heat release rate (HRR) is the amount energy released per unit of time. HRR is measured in Watts (W). A Watt is a Joule (unit of energy) per second (unit of time). The fire service in the United States has traditionally used the British thermal unit (Btu) as a unit of energy. Using this unit of measure, HRR could be expressed in Btu/s. All of this is very interesting, but what does this have to do with flashover? As it turns out, heat release rate has everything to do with flashover!

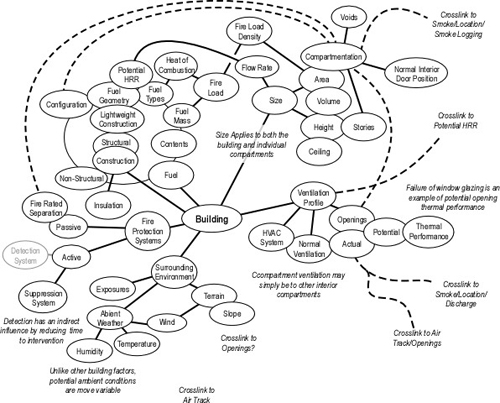

When a fire is unconfined, much of the heat produced by the burning fuel escapes through radiation and convection. What changes when the fire occurs in a compartment? Fire development becomes influenced by the characteristics of the compartment. Other materials in the compartment as well as the walls, ceiling and floor absorb some of the energy released by the fire. Some of the energy is not absorbed, but radiates back to the burning fuel continuing and accelerating the combustion process.

Hot smoke and air heated by the fire become more buoyant and rise, on contact with cooler materials such as the ceiling and walls of the compartment; heat is transferred to the cooler materials, raising their temperature. This heat transfer process raises the temperature of all materials in the compartment. As nearby fuel is heated, it begins to pyrolize. Eventually the rate of pyrolysis may reach a point where flaming combustion can be supported and the fire extends to other fuel packages.

However, the most significant difference with fire in a compartment is the compartment’s ventilation profile. The size, location, and configuration of openings in the compartment influence both the oxygen available for combustion and the retention or escape of thermal energy contained in the hot gases and smoke produced by the fire.

While the “stages of fire” have been described differently in fire service textbooks the phenomenon of fire development is the same. For our purposes, the stages of fire development in a compartment will be described as incipient, growth, fully developed and decay (see Figure 2). Despite dividing fire development into four “stages” the actual process is continuous with “stages” flowing from one to the next. While it may be possible to clearly define these transitions in the laboratory, in the field it is often difficult to tell when one ends and the next begins.

Figure 2. Stages of Fire Development

If the fire releases energy faster than it can escape from the compartment, temperature will increase and if sufficient energy is released, flashover will occur and the fire will transition rapidly from the growth to fully developed stage (see Figure 2). As this occurs, the fire will spread across all combustible surfaces in the compartment and flames will exit through compartment openings.

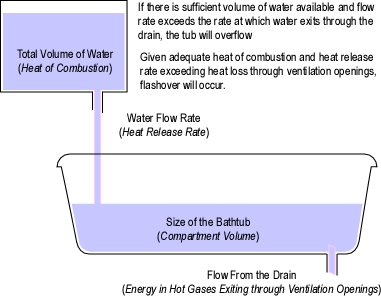

The bathtub analogy (see Figure 3) provides a simple way to explain the relationship between ventilation and flashover in a fuel controlled compartment fire.

Flashover has been analogously compared to the filling of a bathtub with the drain open. In this practical, though not perfect, analogy water represents the heat energy. The quantity of water available is the total heat of combustion of the available fuels (fuel load). The size of the spigot and the water pressure control the amount of water flow that is the heat release rate. The volume of the bathtub is analogous to the volume of the compartment and its ability to contain the heat energy. The size and location of the bathtub drain controlling the rate of water loss is the loss of heat energy through venting and conductance. In this analogy, if the bathtub becomes full and overflows, flashover occurs. (Kennedy & Kennedy, 2003, p. 7)

Figure 3. The Bathtub Analogy

More to Follow

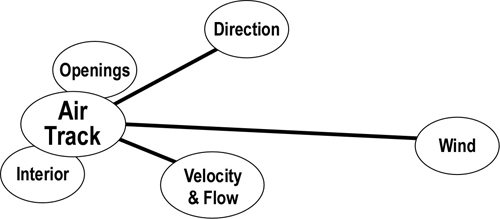

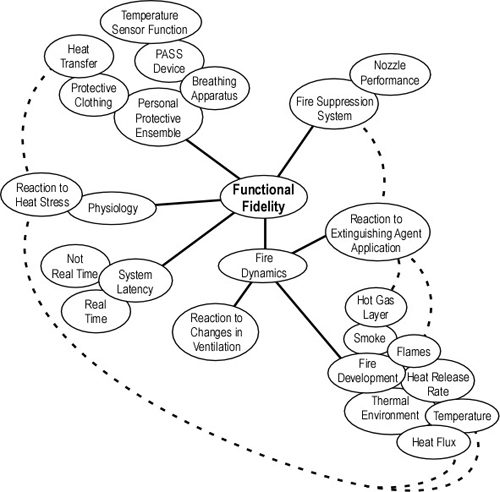

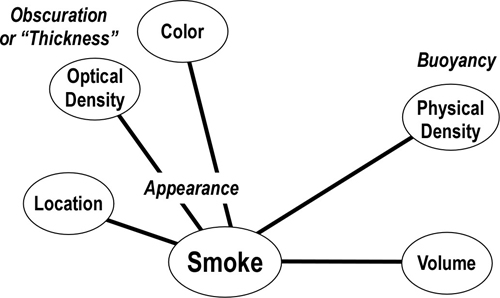

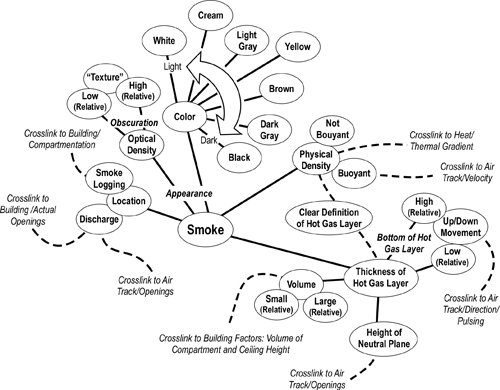

Posts over the next few weeks will continue to examine the process of reading the fire with further exploration of air track, heat, and flame indicators. In addition, I will be continuing this look at the flashover phenomena with a particular emphasis on the relationship between heat release rate, ventilation, and flashover.

Ed Hartin, MS, EFO, MIFireE, CFO

References

Close, K. (2005) Fire behavior vs. human behavior: Why the lessons from Cramer matter. Paper presented at the Eighth International Wildland Fir e Safety Summit, Missoula,MT. Retrieved May 13, 2008 from http://www.myfirecommunity.net/documents/Close.pdf

Drysdale, D. (1998). An introduction to fire dynamics. New York: John Wiley & Sons.

Gorbet, G & Hopkins, R. (2007) The current knowledge & training regarding backdraft, flashover, and other rapid fire progression phenomena. Paper presented at the annual meeting of the National Fire Protection Association, Boston, MA.

Kennedy, P. & Kennedy, K. (2003). Flashover and fire analysis: A discussion of the practical use of flashover in fire investigation. Retrieved July 30, 2009 from http://www.kennedy-fire.com/Flashover.pdf