Effective and Efficient Fire Streams

Thursday, November 26th, 2009It is often stated and commonly believed that it takes gpm to overcome Btu. While I suspect that firefighters understand the underlying intent of this statement, it is actually incorrect as it is comparing apples and oranges. Flow rate is expressed in terms of volume and time (gal/m or l/m). However, Btu (or Joules) is a measure of quantity (more like volume than flow rate).

You can say that it takes gallons (or liters) to overcome Btu (or Joules), But the rate at which energy is absorbed by a fire stream must overcome heat release rate (energy released/unit of time). This concept points to the need for a higher flow rate when the heat release rate from a fire is larger. This leads to another common fire service saying: “Big Fire, Big Water”. While this is not completely incorrect, it is a bit misleading as it does not account for the efficiency of the fire stream in absorbing energy. Not all of the water that leaves the nozzle absorbs the same amount of energy.

Theoretical Cooling Capacity

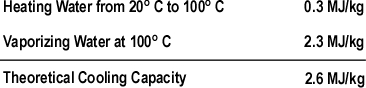

Water is an excellent extinguishing agent because it has a high specific heat (energy required to raise its temperature) and high latent heat of vaporization (energy required to change it from water to steam). As illustrated in Figure 1, conversion of water to steam is most significant as it absorbs 7.5 times more energy than heating water from 20o C (68o F) to its boiling point.

Figure 1. Theoretical Cooling Capacity

However, this only tells us the theoretical cooling capacity of a single kilogram of water at 20o C (68o F) if it is raised to 100o C (212o F) and completely vaporized. Examining theoretical cooling capacity in terms of flow rate requires a bit more work.

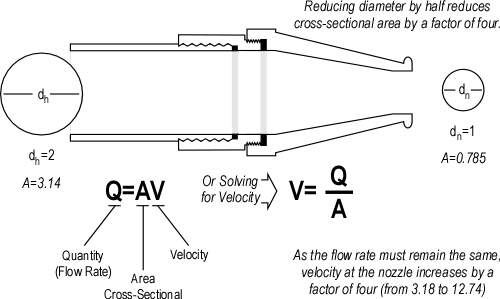

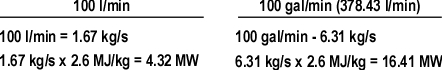

Flow is defined in terms of gallons per minute (gal/m) or liters per minute (l/m) and theoretical cooling capacity of water was defined in terms of energy absorbed per second per unit mass (MJ/kg) we need to work through conversion to common units of measure.

While SI units are simpler to work with, I have worked cooling capacity out in both liters per minute (LPM) and gallons per minute (GPM). However, in that specific heat and latent heat of vaporization are applied to mass rather than volume and Watts are joules per second, it is first necessary to covert flow rate into kg/s

Figure 2. Flow Rate and Theoretical Cooling Capacity

This example assumes instantaneous heat transfer and 100% efficiency in conversion of water to the gas phase. Neither of which is possible in the real world!

Factors influencing effectiveness and efficiency of heat transfer (Svennson, 2002) include:

- Diameter (in the gas layer and on surfaces)

- Temperature (in the gas layer and on surfaces)

- Velocity (in the gas layer)

- Film formation (on surfaces)

- Temperature of the gas layer

- Surface temperature

Fire Stream Efficiency

The firefighter’s power is not simply related to flow rate, but flow rate effectively applied to transfer heat from hot gases and surfaces by changing its phase from liquid (water) to gas (steam). Extinguishing a compartment fire generally involves converting a sufficient flow (gal/m or l/m) of water to steam. So while the “steam” itself does not generally extinguish the fire, the energy absorbed in turning the water to steam has the greatest impact on fire extinguishment.

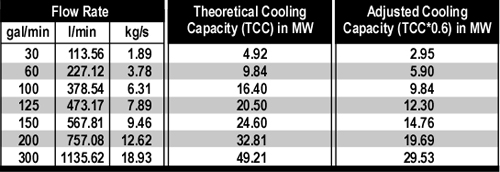

Experimental data (Hadjisophocleous & Richardson, 2005; Särdqvist, S., 1996) has shown that the cooling efficiency of water in both laboratory experiments and actual firefighting operations ranges from 0.2 to 0.6. Särdqvist (1996) suggests that an efficiency factor of 0.2 be used for interior fog nozzles. Based on my personal observations (but no experimental data), I think that Särdqvist’s efficiency factor of 0.2 might be just a bit on the low side. Barnett (as cited in Grimwood,2005) suggests that an efficiency factor of 0.5 be used for solid or straight stream application and 0.75 for fog application. The following table takes a slightly more conservative approach, using 0.6 as an average efficiency factor.

Figure 3. Flow Rate and Adjusted Cooling Capacity

Figure 3 is provided to illustrate the impact of efficiency (or lack thereof) on fire stream cooling capability. The key point is that actual cooling capability is considerably less than the theoretical cooling capacity. Another complication is that in addition to nozzle performance characteristics, nozzle efficiency is also dependent on the skill of the nozzle operator, the manner in which water is applied (straight stream, narrow fog pattern, wide fog pattern), the configuration of the space, and fire conditions. Unfortunately, there is no standardized test with specified conditions that permits comparison of different nozzles and/or methods.

However, the concept of efficiency gives rise to an interesting question. Does a nozzle flowing 100 gpm with an efficiency factor of 0.6 have the same extinguishing capability as 200 gpm nozzle with an efficiency factor of 0.3. This is simple math! The cooling capacity would be identical. While the practical application is more complex (as we do not really know the efficiency factors for the two nozzles and manner in which they are being used), this is worth thinking about.

Flow Rate or Heat Absorption Capacity

CFBT-US Senior Instructor Trainer Matt Leech (LT Tualatin Valley Fire & Rescue) proposed (half in jest) that nozzles should be labeled with their potential cooling capacity rather than flow rate. While this idea did not get significant traction, it is important for firefighters to recognize that flow rate and fire stream characteristics have a significant impact on potential cooling capacity.

Fire Stream Effectiveness

Safe, effective and efficient fire control requires:

- Water application to control the fire environment as well as direct attack on the fire

- Appropriate flow rate for the tactical application (cooling hot, but unignited gases may be accomplished at a lower flow rate than direct attack on the fire)

- Direct attack to exceed the critical flow rate based on the fire’s heat release rate

- Sufficient reserve (flow rate) be available to control potential increases in heat release rate that may result from changes in ventilation

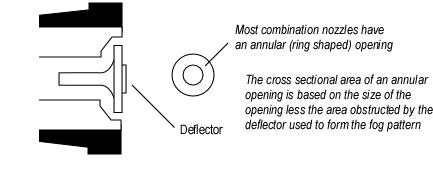

- Water application in a form appropriate to cool its intended target (i.e., small droplets to cool hot gases or to cover hot surfaces with a thin film of water)

- Water to reach its intended target (fog stream to place water into the hot gas layer and a straight or solid stream to pass through hot gases and flames and reach hot surfaces)

- Control of the fire without excessive use of water

Accomplishing this requires different stream characteristics at different times. The characteristics that are optimal for gas cooling are likely quite different than for cooling hot surfaces, particularly when dealing with fully developed fire conditions in a large compartment.

Priorities

As regular readers have likely noted my posting schedule has been a bit off of late. My responsibilities as the new Fire Chief with Central Whidbey Island Fire & Rescue preclude the necessary research and writing necessary to constantly post twice weekly. I will be scaling back to a single post on Thursday for the next few months while I get a handle on my new job and get my family moved to Whidbey Island.

Ed Hartin, MS, EFO, MIFIreE, CFO

References

Grimwood, P. (2005) Firefighting Flow Rate: Barnett (NZ) – Grimwood (UK) Formulae. Retrieved January 26, 2008 from http://www.fire-flows.com/FLOW-RATE%20202004.pdf

Hadjisophocleous, G.V. & Richardson, J.K. (2005). Water flow demands for firefighting. Fire Technology 41, p. 173-191.

Särdqvist, S. (1996) An Engineering Approach To Fire-Fighting Tactics Sweden, Lund University, Department of Fire Safety Engineering

Svennson, S. (2002). The operational problem of fire control (Report LUTVDG/TVBB-1025-SE). Sweden, Lund University, Department of Fire Safety Engineering.