Understanding Flashover:

The Importance of Air Track

Monday, August 31st, 2009

This is the fourth in a series of posts dealing with flashover, to review prior posts see:

- Understanding Flashover: Myths and Misconceptions

- Understanding Flashover: Myths and Misconceptions: Part 2

- The Ventilation Paradox

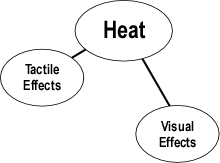

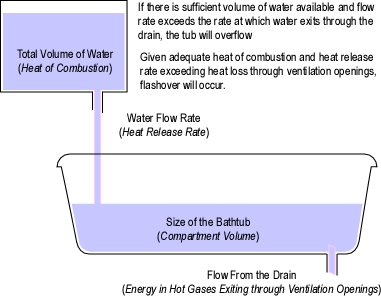

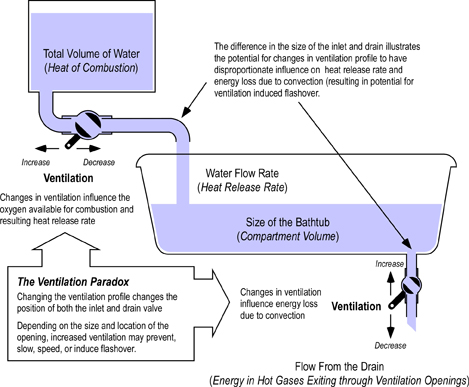

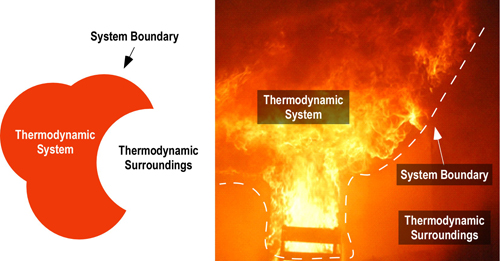

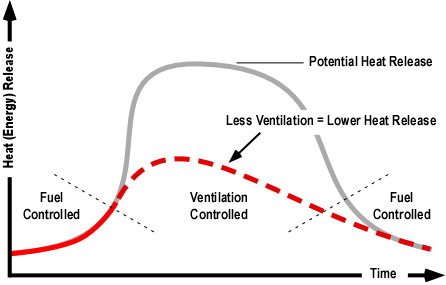

As previously discussed flashover requires sufficient heat release rate for the temperature of fuel packages within a compartment to increase sufficiently to ignite and the fire to rapidly transition to the fully developed stage. However, during fire development in a compartment the fire often becomes ventilation controlled, with fire growth and heat release rate limited by the available air supply. In some cases, the fire generates sufficient heat release rate despite being ventilation controlled. In others, there is insufficient oxygen in the air supplied for the fire to reach flashover (unless ventilation is increased). All of this is fairly simple and straightforward if we are examining fire in a single compartment. This simple explanation of flashover is based on fire development in a single compartment, such as that described in the ISO 9705 Fire Tests-Full Scale Room Fire Tests for Surface Products6American Society for Testing and Materials (ASTM) Standard E 603-6 (Figure 1)

Figure 1. Full Scale (Six Sided) Room Fire Test Compartment

Note: Underwriters Laboratory (UL) fire test photo adapted from Fire Behavior in Single Family Dwellings, [PowerPoint Presentation], National Fire Academy.

Things get a bit more complex when a fire occurs in a multi-compartment building as individual compartments are interconnected smoke and flames may extend from compartment to compartment throughout the building.

Ventilation and Air Track

Contrary to the common fire service definition of ventilation as “[planned and] systematic removal of heated air, smoke, and fire gases and replacing them with cooler air (IFSTA, 2008), ventilation is simply the exchange of the atmosphere inside the building with that which is outside. This process is ongoing under normal, non-fire conditions. However, under fire conditions, ventilation also involves movement of smoke and air between compartments as well as discharge of smoke from the building and intake of air from outside the structure.

Remember! If you can see smoke coming from the building, ventilation is occurring (but not necessarily the type or amount of ventilation that you need to effectively control the fire environment and the fire).

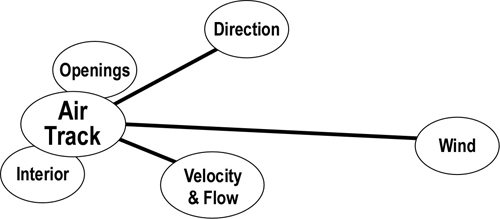

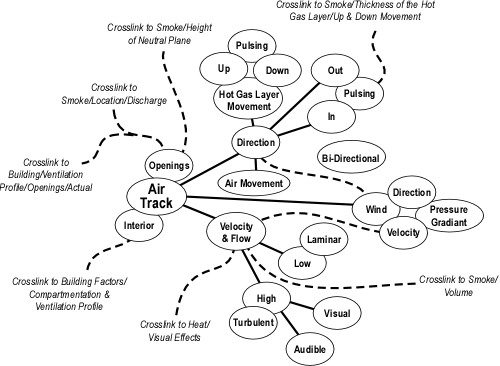

The term air track is used to describe the characteristics of air and smoke movement (e.g., direction, velocity). The movement of both air and smoke are important, but the direction and path of smoke movement is particularly significant for several reasons:

- Smoke is fuel

- Hot smoke has energy

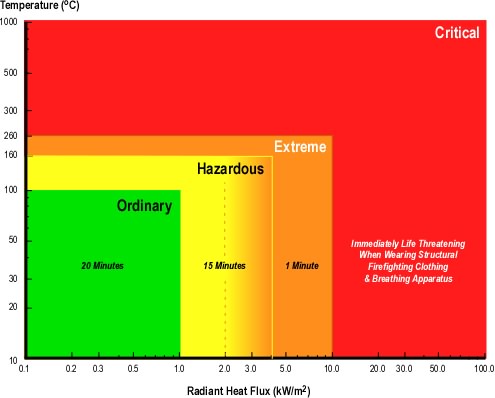

Through convection, smoke carries energy away from the fire compartment and transfers this energy to objects having lower temperature (such as other fuel packages or firefighters working inside the building). The rate of heat transfer is substantially dependent on temperature difference and in the case of convection on the velocity of the hot gases. Higher velocity and turbulence results in a higher rate of convective heat transfer (much the same as the increase in wind chill as wind speed increases in a cold environment).

Air Track on a Single Level

Examination of air track on a single level provides a simple way to illustrate the influence of air track on the movement of smoke (think fuel and energy) from compartment to compartment, fire extension, and multi-compartment flashover.

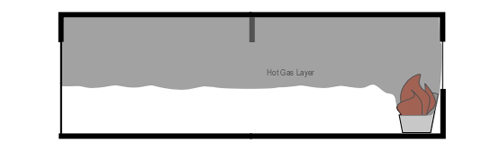

With no significant ventilation (with the exception of slight building leakage) smoke will fill the fire compartment and extend through openings such as doorways to adjacent compartments (see Figure 2). If insufficient oxygen is available from the air within the compartments the fire will become ventilation controlled and growth may slow and the fire may decay (heat release rate lessens)

Figure 2. Limited Ventilation

Note: Unless the building is tightly sealed, there is likely to be some leakage resulting in smoke discharge and inward movement of air.

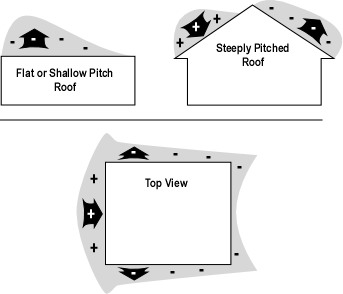

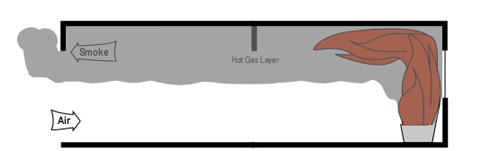

If an opening is made in the presently uninvolved compartment, smoke will move from the fire to the opening, exiting out the upper area of the opening while cool air moves inward through the bottom of the opening and towards the fire (see Figure 3). This is a bi-directional air track.

Figure 3: Single Opening with Bi-Directional Air Track

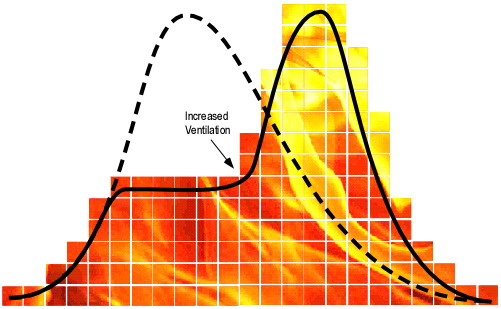

As pointed out in The Myth of the Self-Vented Fire and The Ventilation Paradox, providing additional oxygen to a ventilation controlled fire results in increased heat release rate and may result in ventilation induced flashover. However, it is important to consider how this impacts adjacent compartments as well.

Increased heat release rate in a still ventilation controlled fire results in higher hot gas layer temperatures and increased smoke production. Increasing temperature and volume of the hot gas layer will cause it to lower and velocity to increase as the smoke moves through adjacent compartments and out ventilation openings. This increases both radiant and convective heat transfer and potentially speeds progression to flashover in adjacent compartments.

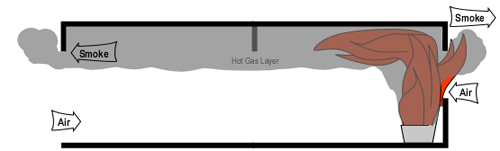

Horizontal tactical ventilation can be accomplished rapidly and may, under some conditions, be a useful approach to improving interior conditions. Increasing the number and size of horizontal openings can raise the level of the hot gas layer (by providing additional exhaust). However, when dealing with a ventilation controlled fire the increased oxygen supplied to the fire will increase heat release rate. In addition, in the absence of wind or application of positive pressure at the entry point, two openings at the same level will result in a bi-directional air track at both openings as illustrated in Figure 4.

Figure 4. Two Openings with a Bi-Directional Air Track

If heat release rate is sufficient, this may result in vent induced flashover in the compartments between the fire and the exhaust openings as illustrated in the following video clip.

Important! Horizontal ventilation is not a bad tactic. However, it is essential to recognize and manage the air track as well as ensuring that ventilation is coordinated with fire attack.

More to Follow

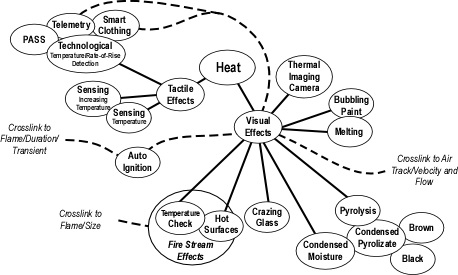

Examination of the flashover phenomenon will continue with a case study involving a 1999 fire in a Washington, DC townhouse that resulted in the line of duty deaths of two firefighters. This incident is particularly important as it is one of the first times that the National Institute of Standards and Technology (NIST) Fire Dynamics Simulator (FDS) and Smokeview were used for forensic fire scene reconstruction. This data, in conjunction with the District of Columbia Fire and EMS Reconstruction Report and National Institute for Occupational Safety and Health (NIOSH) Death in the Line of Duty Report provides a solid basis for understanding the impact of burning regime and air track in multi-compartment, ventilation induced flashover.

Ed Hartin, MS, EFO, MIFireE, CFO

References

International Fire Service Training Association (IFSTA). (2008). Essentials of firefighting (5th ed.). Stillwater, OK: Fire Protection Publications.