Decay Stage Fires:

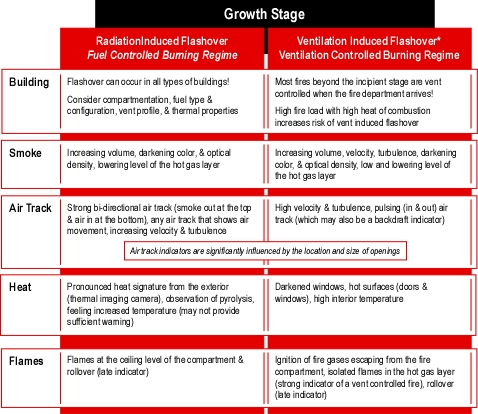

Key Fire Behavior Indicators

Thursday, October 29th, 2009

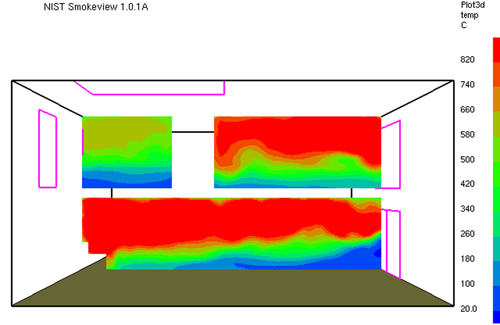

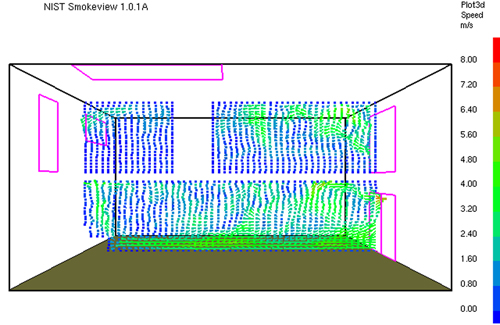

As discussed in Flashover and Fully Developed Fires: Key Fire Behavior Indicators, providing additional oxygen to a ventilation controlled fire will result in a corresponding increase in heat release rate (HRR). This occurs because oxygen is required to release the chemical potential energy in fuel. The energy released per unit of mass of oxygen is remarkably consistent for both natural and synthetic organic (carbon containing) fuels.

Thornton’s Rule specifies that one kilogram (1 kg) of oxygen is required to release 13.1 mega joules (MJ) of energy. Multiplying 13.1 MJ/kg of oxygen by 21% (the concentration of oxygen in air) provides a value of 2.751 MJ/kg of air. The Society of Fire Protection Engineering (SFPE) Handbook of Fire Protection Engineering (SFPE, 2002) rounds this value to 3.0 MJ/kg of air. For a more detailed discussion of Thornton’s Rule and the relationship between fuel, oxygen, and energy release, see Fuel and Ventilation.

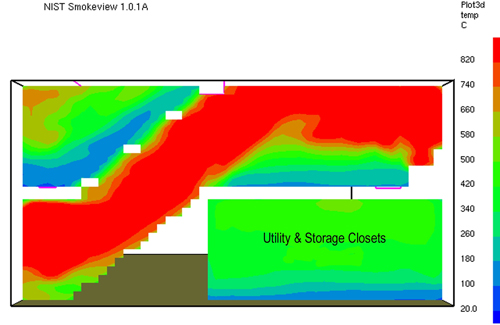

Decay Stage

A compartment fire may enter the decay stage as the available fuel is consumed or due to limited oxygen. As discussed in relation to flashover, a fuel package that does not contain sufficient energy or does not have a sufficient heat release rate to bring a compartment to flashover, will pass through each of the stages of fire development (but may not extend to other fuel packages). On a larger scale, without intervention an entire structure may reach full involvement and as fuel is consumed move into the decay stage. However, there is another, more problematic way for the fire to move into the decay stage. When the ventilation profile of the compartment or building does not provide sufficient oxygen, the fire may move into the decay stage. Heat release rate decreases as oxygen concentration drops. While temperature follows heat release rate, the temperature in decay stage fire may remain high for some time (particularly in well insulated, energy efficient buildings). This presents a significant threat as solid fuel packages continue to pyrolize and the involved compartment(s) may contain a high concentration of hot, pyrolized fuel, and flammable gaseous products of incomplete combustion.

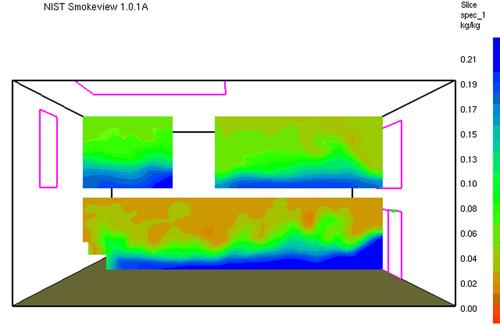

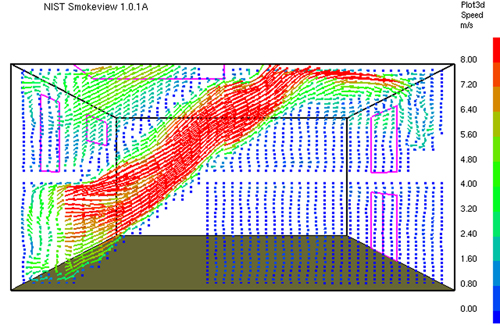

Ventilation Controlled Fires

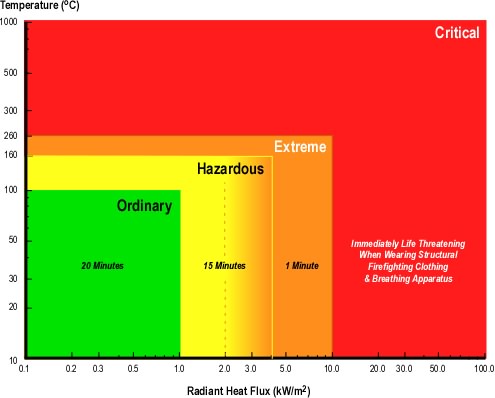

Under ventilation controlled conditions excess pyrolizate and flammable products of combustion present in smoke are a significant hazard to firefighters. Let’s go back to the fire triangle to examine the nature of this threat. While fuel, heat, and oxygen are present in proportion to support combustion where the fire is burning, the heat of the fire is pyrolyzing more fuel vapor than the fire can consume. In addition, incomplete combustion results in production of flammable gases such as carbon monoxide. The speed of fire development is limited by the availability of atmospheric oxygen provided by the current ventilation profile of the compartment or building.

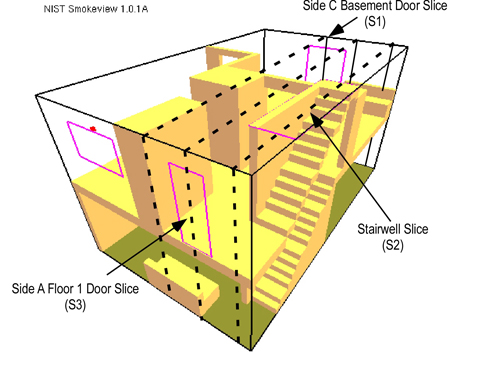

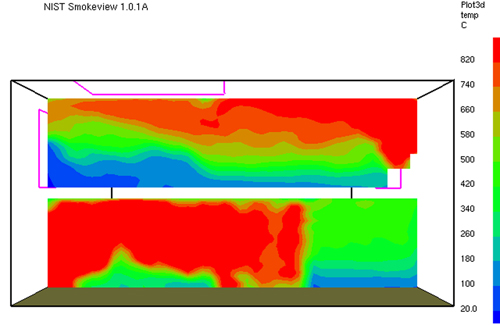

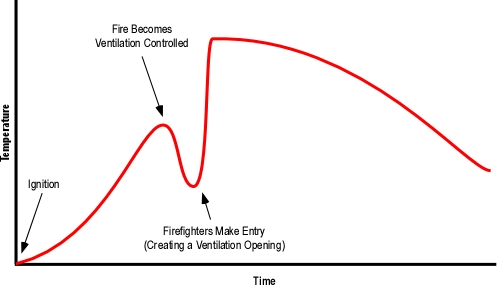

In his presentation, Fire Dynamics for the Fire Service, Dan Madrzykowski of the National Institute of Standards and Technology (NIST) discussed the increased potential for ventilation controlled, decay stage fires in today’s modern, energy efficient structures. Dan presented the time temperature curve illustrated in Figure 1 to describe modern fire development and the potential influence of firefighting tactics.

Figure 1. Fire Development in the Modern Environment

Note: Adapted from National Institute of Standards and Technology (NIST) Fire Dynamics for the Fire Service, D. Madryzkowski.

The data in Figure 1 could be presented as HRR over time as well, but as HRR cannot be measured outside the lab, temperature is often used to describe fire development in full-scale tests. When the fire is burning in a ventilation controlled state, any increase in the supply of oxygen to the fire will result in an increase in heat release rate. Increase in ventilation may result from firefighters making entry into the building (the access point is a ventilation opening), tactical ventilation (performed by firefighters), or unplanned ventilation (e.g., failure of window glazing due to elevated temperature).

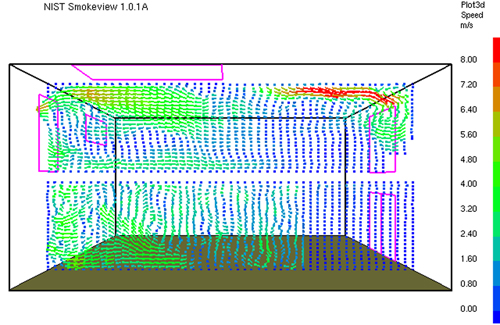

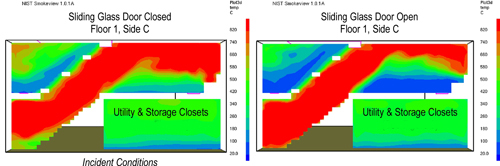

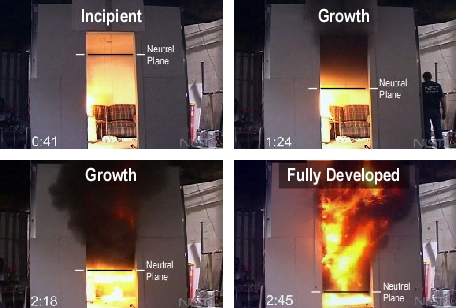

It is essential to recognize when the fire is, or may be ventilation controlled and the influence of planned and unplanned changes in ventilation profile. Most compartment fires that progress into the growth stage are ventilation controlled when the fire department arrives. A bi-directional air track (smoke out the top and air in the bottom) is often a significant indicator of a ventilation controlled fire, but what about before the door is open?

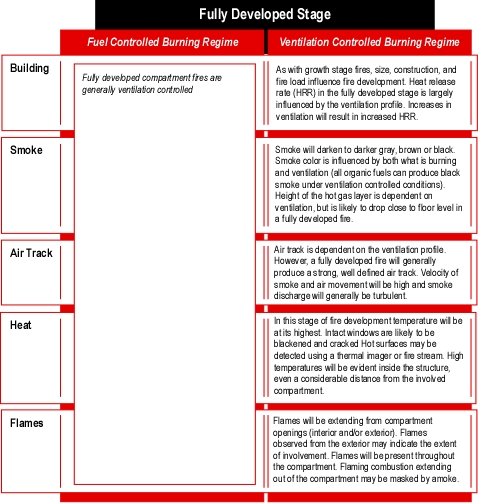

Figure 2. Assessment of Conditions at the Door

As combustion becomes more incomplete, smoke production increases, color darkens, and optical density increases. However, these indicators may be subtle when observing fire conditions from the exterior. Assessment of conditions must continue after making entry. Smoke and air track indicators can be particularly useful in addressing the stage of fire development and burning regime when working inside. In addition, flames moving through the hot gas layer are a strong indicator of a ventilation controlled fire (as well as a threat to your safety which should be dealt with immediately).

Ventilation Induced Extreme Fire Behavior

When the fire is ventilation controlled, increased air supply to the fire will result in increased heat release rate and depending on conditions may result in extreme fire behavior such as flashover or backdraft. While both phenomena result from an increase in ventilation, vent induced flashover and backdraft are different phenomena. The conditions required for a ventilation induced flashover are 1) a compartment fire which has an insufficient HRR to reach flashover due to ventilation controlled combustion, and 2) insufficient concentration of excess pyrolizate and unburned products of incomplete combustion to result in a backdraft. While complex, the key determinant in the occurrence of a backdraft is likely to be the concentration of gas phase fuel within the compartment.

While these phenomena are different, both present a significant threat to firefighters. Rapid fire progress due to ventilation induced flashover or backdraft is not an instantaneous process. Depending on a number of variables such as the location of the fire, current level of involvement, temperature of the smoke (hot gas) layer, and extent of the increase in ventilation these rapid fire progress phenomenon may take some time to occur. However, when it does, fire development will be extremely rapid! Firefighters entering a compartment or building containing an under ventilated fire must be aware of and manage the hazards presented by the potential for rapid fire progress. Remember, many if not most fires that have progressed beyond the incipient stage before firefighters arrival are ventilation controlled and present the potential for rapid fire progress with increased ventilation (see Situational Awareness is Critical).

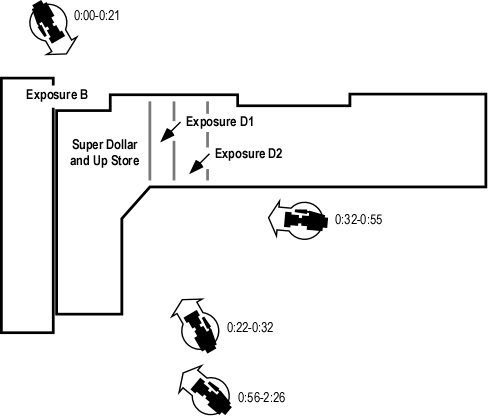

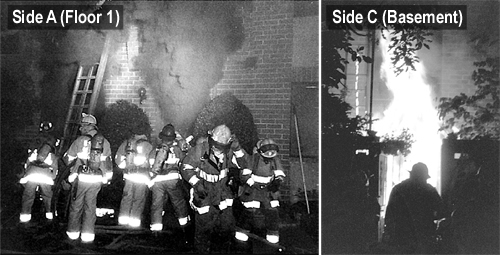

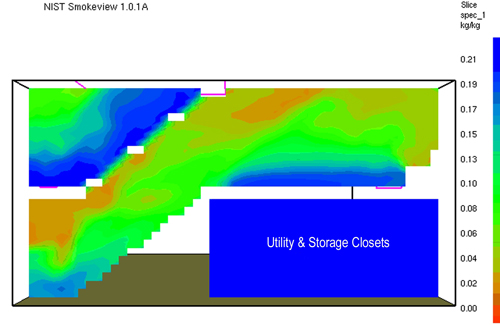

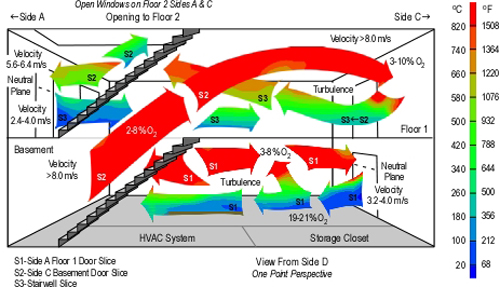

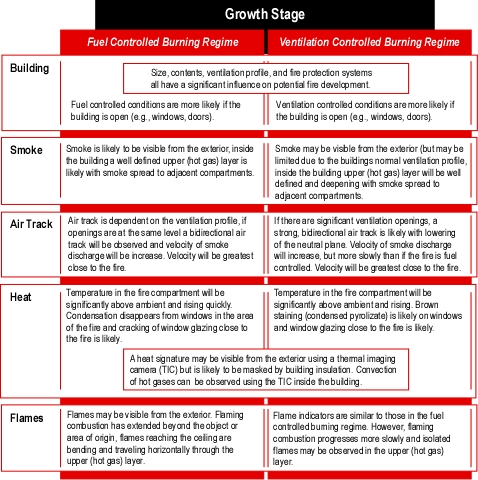

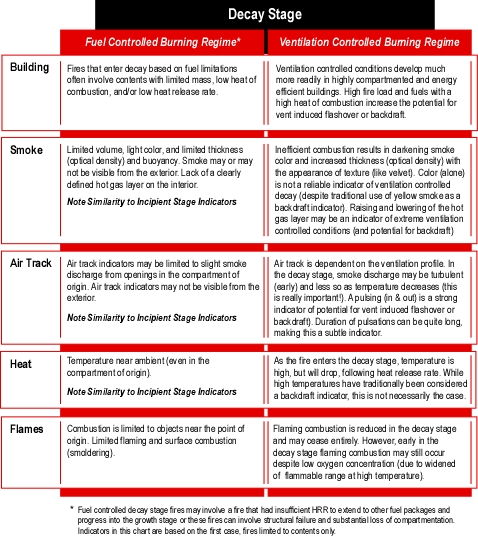

Figure 3 lists the fire behavior indicators related to ventilation controlled decay stage conditions and the potential for ventilation induced extreme fire behavior. It is important to note that there are not always clear distinctions in the visual indicators for vent induced flashover and backdraft.

Figure 3. FBI: Decay Stage

Be Wary

Decay stage indicators can sometimes be subtle and conditions may not look too bad (maybe like an incipient or early growth stage fire if you are not paying close attention and consider the possibilities).

It is often assumed (incorrectly) that ventilation induced extreme fire behavior (flashover or backdraft) will occur immediately after an increase in ventilation. Depending on fire conditions and building configuration there may be a significant time lag between ventilation and resulting changes in fire behavior. When ventilation controlled decay conditions are indicated (or suspected), firefighters should move cautiously and take action to change conditions inside the building or compartment (e.g., gas cooling, ventilation).

You have responded to a fire in a one-story single family dwelling of wood frame construction. A fire which started in a bedroom on the Alpha Bravo corner of the structure has gone from fully developed to the decay stage due to a lack of oxygen as building openings (doors and windows) remain closed and intact.

- What conditions would you expect to see from the exterior of the structure?

- What indicators may be visible from the front door as you make entry?

A fire in the decay stage (particularly when this is due to limited oxygen) still presents a significant threat as conditions can change rapidly.

- If the door at your entry point remains fully open, how will this influence fire behavior (assuming no other ventilation has been performed)?

- How would fire behavior be influenced if a window (or windows) in the fire compartment are opened along with the door at your entry point?

- What indicators would you anticipate observing as you traveled through the living room to the hallway leading to the bedroom?

- What conditions would you find in the hallway outside the fire compartment?

After making entry, consider if conditions are different than you anticipated?

- Why might this be the case?

- What differences in conditions would be cause for concern?

Late Breaking News

I have been selected to serve as Fire Chief with the Central Whidbey Island Fire District in Washington and anticipate starting in my new position by mid November.

Over the next year I will also be serving on an advisory panel to assist Underwriters Laboratory with a research project on to examine the impact of ventilation on fire behavior in legacy and contemporary construction. Output from this project will include a formal technical report, articles in fire service publications, presentation to the fire service community, and a stand-alone web-based training module.

References

Society of Fire Protection Engineers (SFPE). (2002). The SFPE handbook of fire protection engineering (3rd ed.). Quincy, MA: National Fire Protection Association.

Madrzykowski, D. Fire dynamics for the fire service [PowerPoint Presentation], Gaithersburg, MD: National Institute of Standards and Technology.