Effective and Efficient Fire Streams: Part 3

Thursday, December 31st, 2009The first two posts in this series, Effective and Efficient Fire Streams, and Effective and Efficient Fire Streams: Part 2, discussed theoretical cooling capacity, fire stream efficiency, flow rate, nozzle design characteristics and methods of use. This post drills down with a look at the relationships between the pump, hose, and nozzle in developing effective and efficient fire streams.

Where to Start?

It is likely that the most common system for developing effective and efficient fire streams involves use of combination nozzles having a designed operating pressure of approximately 100 psi (690 kPa) and what my British and Australian colleagues would refer to as “layflat” hose with a diameter between 1-1/2” (38 mm) and 2” (52 mm). As this type of system seems to be common to most fire services (with a few variations), this is a good place to start.

Hydraulics

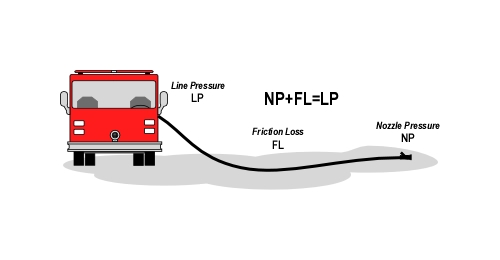

Developing effective and efficient fire streams requires an understanding of basic principles of fireground hydraulics. As discussed in earlier posts, each nozzle has a designed operating pressure. In order to provide this pressure at the nozzle, it is necessary to overcome loss of pressure in hoselines due to friction loss and increases in elevation.. Add To keep this discussion simple, the pump and nozzle will be at the same elevation.

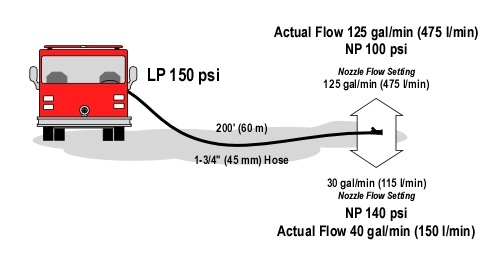

Figure 1. Basic Handline Hydraulics

The major factors influencing friction loss in a hoseline are flow rate and diameter of the hoseline. The Pumping Apparatus Driver/Operator Handbook (IFSTA, 2006) identifies four friction loss principles:

First Principle: All other conditions being equal, friction loss varies directly with the length of the hoseline.

Second Principle: When hoseline diameter remains constant, friction loss varies approximately with the square of the increase in flow rate. Doubling the flow increases friction loss by a factor four.

Third Principle: At the same flow rate, friction loss varies inversely as the fifth power of the diameter of the hoseline (increasing hose diameter, even a small amount has a dramatic effect on friction loss. Increasing hose diameter from 1-1/2” (38 mm) to 1-3/4” (45 mm) reduces friction loss by 46% (1.505/1.755=0.46).

Fourth Principle: If hose diameter and flow rate are held constant, friction loss is independent of pressure.

Apparatus operators must understand these basic concepts and be proficient at determining the line pressure required to develop adequate nozzle pressure to produce the necessary reach and droplet size for effective and efficient fire control operations.

Scalability

Critical and optimal flow rate are dependent on the heat release rate from the fire. The higher the heat release rate, the higher the flow rate necessary to achieve fire control. However, the flow rate required for gas cooling (unignited gas phase fuel) is not so dependent on HRR! Cooling unignited gases is most effective at a considerably lower flow rate. 30 gal/min (115 l/min) to 60 gal/min (230 l/min) is often sufficient for gas cooling (unless compartment size is extremely large).

Single flow nozzles are simple to operate as control is limited to the angle of the fog pattern and the shutoff valve. The term single flow is a bit misleading in that flow can be varied using the shutoff valve. Partially opening the shutoff valve will provide a reduced flow rate. However, partially opening the valve also provides considerably lower nozzle pressure (at the orifice), resulting in poor stream performance (limited reach and large droplet size). If a nozzle is designed to develop the low flow rate and small droplet size that is typically optimal for gas cooling, it may not have sufficient flow for direct attack on larger fires or fires in larger compartments. On the other hand, nozzle designed for higher flow rates may be ideal for direct attack on larger fires or large compartments, but are inefficient and in some cases ineffective when used for gas cooling.

Ideally, the hose and nozzle system should be scalable to provide effective and efficient operation over a fairly wide range of flow rates. At the low end, the nozzle should be capable of gas cooling at 30 gpm (115 lpm). The upper end of flow capability for direct attack has room for considerable debate.

Some agencies such as the New South Wales Fire Brigades in Australia uses the Akron Turbojet with flow settings of 30, 60, 95, & 125 gal/min (115, 230, 360, 475 l/min). On the other hand, many fire departments in the United States use nozzles having upper end flow rates of 150-200 gal/min (568-757 l/min). Having a higher flow capability provides the ability to deal with higher HRR and larger size compartments typical in contemporary residential structures and commercial buildings.

Variable flow and automatic nozzles provide the capability to vary flow rate as needed to deal with varied tactical applications and fire conditions. However, each accomplishes this task in a different manner.

Variable Flow Nozzles

When using a variable flow nozzle, the size of the nozzle orifice can be changed manually to provide several specific flow rates at the designed nozzle pressure. This requires that the apparatus operator know the flow setting of the nozzle as well as the length of line in order to determine the line pressure required to develop the correct nozzle pressure. At first glance, it appears that changing flow rates on the fly would require a great deal of radio communication between the nozzle team and apparatus operator (communication of flow setting each time it is changed). However, this challenge can easily be overcome!

Consider what happens when the nozzle operator changes flow setting and the apparatus operator maintains the same line pressure. If the flow setting is reduced (decreasing the orifice size), flow rate will be decreased, reducing friction loss in the hoseline. As the line pressure remains the same, the pressure that is not used to overcome friction loss increases nozzle pressure. For example, if a 200’ (60 m) long 1-3/4” (45 mm) hoseline equipped with a variable flow nozzle such as an Akron Turbojet is flowing 125 gal/min (475 l/min) at a nozzle pressure of 100 psi (690 kPa) and the nozzle operator changes the flow setting to 30 gal/min (115 l/min) and discharge pressure remains constant, the flow rate will be reduced to 40 gal/min (150 l/min) at a nozzle pressure of 140 psi (965 kPa) (see Figure 2).

Figure 2. Changes in Flow Rate and Nozzle Pressure

Note: The preceding example is based on tests conducted with an Akron Turbojet variable flow nozzle.

How does the reduced flow rate and increased nozzle pressure impact on fire stream effectiveness and efficiency? Increased velocity of discharge (resulting from the higher nozzle pressure) results in reduced droplet size, increasing the effectiveness and efficiency of the stream when used for gas cooling. The reduced flow rate may be insufficient for direct attack on larger fires, but the nozzle operator can quickly return to a higher flow rate by adjusting the nozzle flow control. Pumping to deliver maximum flow allows the nozzle operator to select the flow rate and nozzle pressure that is appropriate based on conditions.

Automatic Nozzles

Automatic nozzles maintain a relatively constant nozzle pressure through a given flow range. The nozzle operator controls flow using the shutoff (opening the nozzle partially provides a lower flow rate than when the nozzle is opened fully).

The shutoff valve controls both water application and flow rate, automatic nozzles are a bit simpler to use, but unlike the example provided on how to maximize the capability with the variable flow nozzle, nozzle pressure remains constant (e.g., 100 psi (690 kPa).

System Design

The starting point for designing an effective system to develop effective and efficient fire streams needs to consider the desired flow rate, typical length of hoselines required, and tactical applications. Remember there is no universal, one size fits all, answer to this question. Fire services around the world successfully use a variety of different systems. Consider the following as a starting point:

- Both variable flow and automatic nozzles can be used effectively to apply water at varied flow rates. Automatic nozzles are simpler to operate (as they have fewer controls), but at lower flow rates are likely to develop larger droplets than variable flow nozzles operated at over 100 psi (690 kPa).

- Hoseline diameter should be sufficient to develop the desired flow rate given the likely attack line length. Remember that as hoseline diameter increases, friction loss decreases (but so may mobility).

- Pumping for maximum flow from the nozzle provides the nozzle operator with maximum flexibility as flow rate can be selected based on conditions. If other than maximum flow is selected as the standard flow rate it is important to train nozzle operators to request that the apparatus operator increase discharge pressure to provide maximum flow if needed.

The next post in this series will examine applications of high pressure and ultra-high pressure systems for developing effective and efficient fire streams. While considerably different than the system described in this post, this technology shows promise in expanding the range of tools available for fire control operations.

Ed Hartin, MS, EFO, MIFireE, CFO

References

International Fire Service Training Association (IFSTA). (2006). Pumping apparatus driver/operator handbook (2nd ed). Stillwater, OK: Fire Protection Publications.