Positive Pressure Ventilation:

Did You Ever Wonder Why?

May 18th, 2009

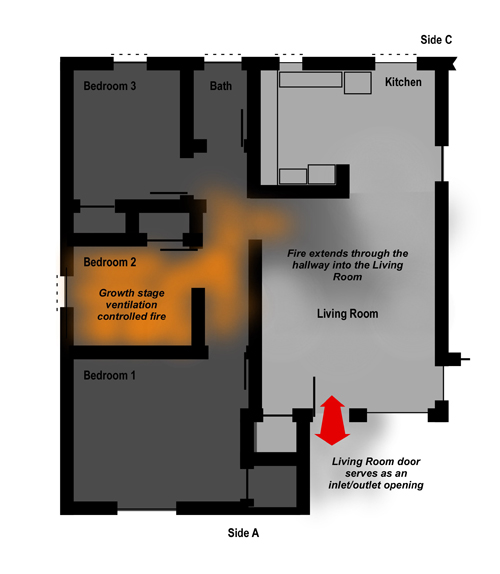

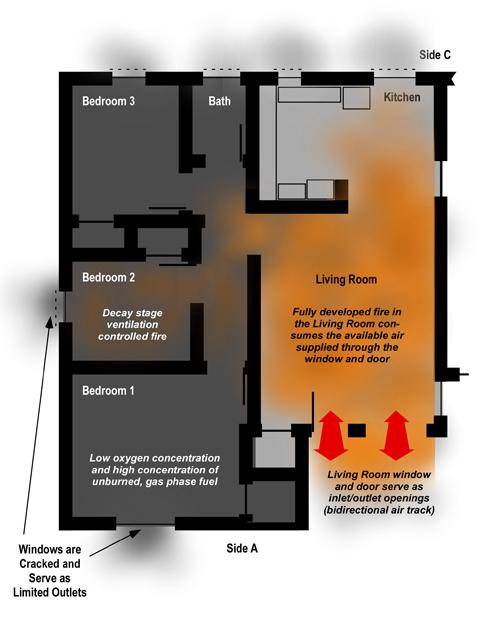

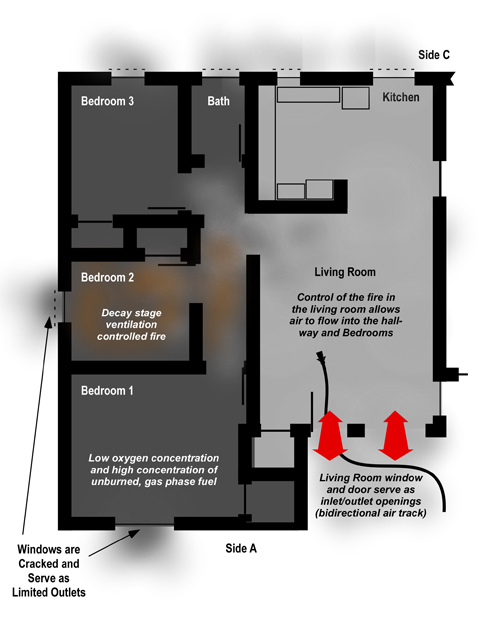

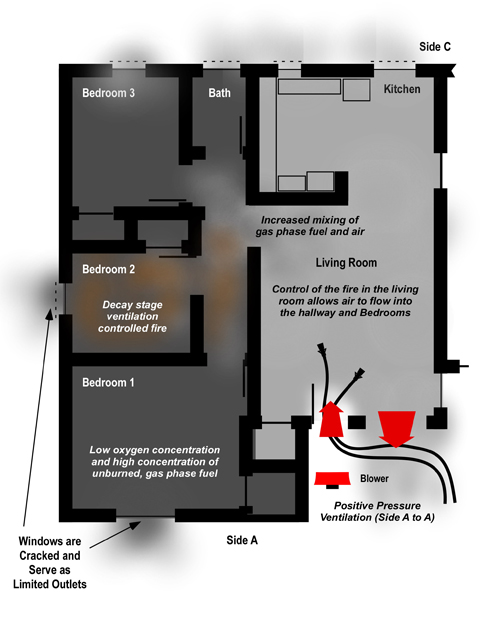

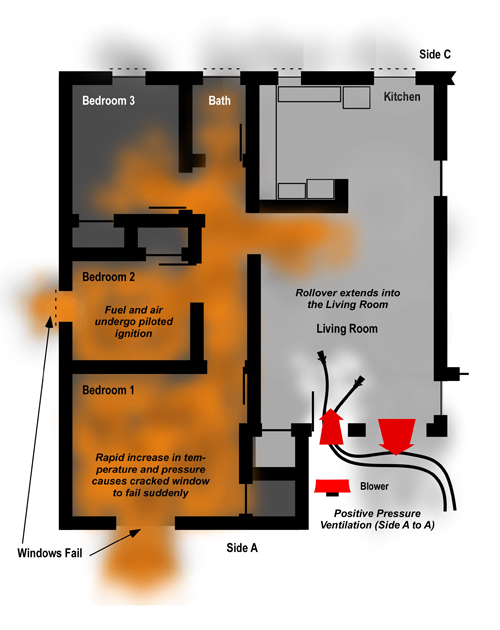

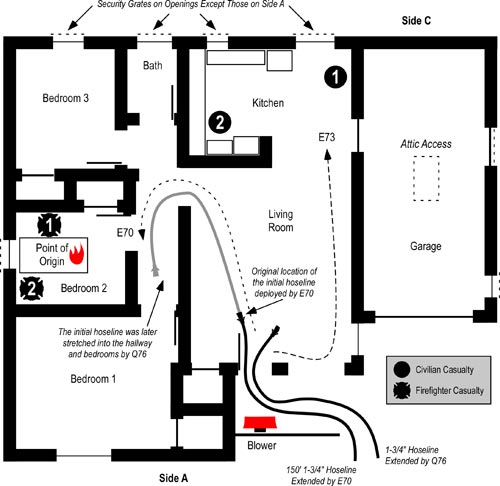

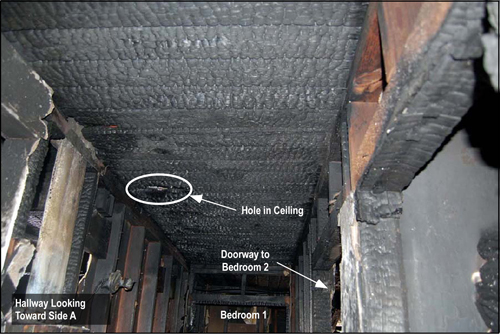

Effective use of positive pressure ventilation aids in fire control and provides increased tenability throughout the fire building. However, inappropriate or ineffective use of this tactic has resulted in numerous near misses, injuries, and more than a few line of duty deaths. In many of these cases, positive pressure was applied with an inadequate exhaust opening.

Find more videos like this on firevideo.net

Did you ever wonder why the size and location of the exhaust opening is critical to safe and effective use of positive pressure ventilation? If not, maybe you should!

A Quick Review

As discussed in an earlier post (see Language and Understanding: Extreme Fire Behavior), common language and definitions are critical to developing a shared understanding. To that end, I want to start this examination of positive pressure ventilation (PPV) with a brief review of terminology used in this post.

Ventilation: The exchange of the atmosphere inside a compartment with the atmosphere outside the compartment. Ventilation is ongoing in all habitable spaces. Under fire conditions, this involves exit of smoke and intake of fresh air (if smoke is visible, ventilation is occurring).

Tactical Ventilation: Planned, systematic, and coordinated removal of heat, smoke, and fire gases (fire effluent) and their replacement with fresh air. There are three important parts of this definition, 1) tactical ventilation is part of the overall tactical plan and is coordinated with other fireground operations (particularly fire control), 2) hot fire effluent is removed, and 3) fresh (cooler) air is introduced into the compartment.

Note: I gave a bit of thought to use of the terms smoke and fire effluent in this discussion of ventilation. The International Standards Organization (ISO) definition of smoke focuses on the visible products of combustion while fire effluent includes all gaseous, aerosol, and particulates generated by combustion. The National Fire Protection Association (NFPA) definition of smoke is comparable to the ISO definition of fire effluent. Given that the traditional definition of (tactical) ventilation refers to “heat, smoke, and fire gases” (IFSTA, 2008, p. 541), I will use the term fire effluent as the broader, more encompassing term (inclusive of smoke and fire gases).

Natural Ventilation: Use of pressure and density differences generated by the higher temperature of gases inside the compartment than outside and ambient wind conditions to accomplish the exchange of hot fire effluent and air.

Assisted Ventilation: These tactics use mechanical or hydraulically generated pressure to influence and increase the exchange of fire effluent and air. Assisted ventilation includes the use of fog streams and fans to reduce pressure at the exhaust opening (negative pressure ventilation) and use of fans or blowers to increase pressure at the inlet opening (positive pressure ventilation).

Positive Pressure Ventilation (PPV): Use of a blower at the inlet opening to increase the pressure differential between the inlet and exhaust opening to control and increase the exchange of fire effluent and air.

Positive Pressure Attack (PPA): This term was coined by Garcia, Kauffmann, & Schelble (2006) to differentiate positive pressure ventilation initiated prior to fire attack from use of this tactic following fire control operations. From a physics perspective, PPV and PPA are the same, the term PPA simply designates the sequence in which the tactic is performed.

Exhaust Opening: The opening(s) used for removal of fire effluent. Note that this opening may be created by unplanned ventilation due to fire effects, civilians, or freelancing responders or it may be created as the result of tactical action. Remember that any location where flames and/or smoke is visible is an exhaust opening.

Inlet Opening: The opening(s) used to introduce fresh air into the compartment. As with exhaust openings, inlet openings may be unplanned or planned. Openings may serve simply as an inlet or may serve as both an inlet and outlet with fire effluent exiting at the top and air entering at the bottom (bi-directional air track).

Smoke Movement in Buildings

Fluids (like fire effluent) flow from areas of higher pressure to areas of lower pressure. In a compartment fire, energy released by combustion raises the temperature of the fire effluent and entrained air. As temperature increases, gases expand and become less dense (more buoyant). However, when gases are confined, increased temperature results in increased pressure. These differences in density and pressure result in movement of smoke out of the compartment and inward movement of air from outside the compartment. This exchange may be through normal building leakage, unplanned ventilation, or tactical ventilation.

The pressure generated by a fire inside a compartment is dependent on the heat release rate, ventilation (openings), and resulting temperature inside the compartment. However, NFPA 92A Standard for Smoke-Control Systems Utilizing Barriers and Pressure Differences (NFPA, 2006) specifies pressure differences in non-sprinklered buildings of between 12.5 Pascal (Pa) and 44.8 Pa to overcome the pressure resulting from hot gases at a temperature of 927o C (1700o F) next to the smoke barrier (these pressures include a 7.4 Pa safety factor). If the safety factor is removed, the pressure generated by a fire in a non-sprinklered occupancy would likely be between 5 Pa and 37.3 Pa. All very interesting, but what is a Pascal?

While firefighters in the United States are generally familiar with pounds per square inch (psi) as a unit of measure for pressure, the standard international unit for pressure is the Pascal (P). A Pascal is an extremely small unit (1 psi = 6895 Pa) roughly equivalent to the pressure exerted by a sheet of writing paper laying on a flat surface. As you can see, the pressure generated by the fire is quite small, but more than adequate to result in significant movement of fire effluent!

Two key points that influence movement of fire effluent and ventilation under fire conditions:

- If the temperature of fire effluent is higher than that of the ambient air it will tend to rise.

- Fire effluent flows from areas of higher pressure to areas of lower pressure.

PPV Basic Concepts

Many firefighters think that they understand positive pressure ventilation and how it should (and should not) be used on the fireground. Some do. However, there are a number of common misconceptions and a great deal of misunderstanding when it comes to effective application of this tactic.

A good starting point is to examine the fundamental purpose of the use of positive pressure in tactical ventilation and anti-ventilation. “The purpose of the positive pressure ventilation fan is to create pressures higher than that of the fire to manage where the smoke and hot gases flow” (Kerber & Madrzykowski, 2008). When used in tactical ventilation, positive pressure can be used to control air track and speed the removal of fire effluent from the compartment. In anti-ventilation (e.g., pressurization of a stairwell or attached exposure), positive pressure is used to confine the fire effluent.

The basic sequence of positive pressure tactical ventilation is as follows

- Size-up and dynamic risk assessment (ongoing)

- Determination that positive pressure is indicated (and not contraindicated)

- Identification of appropriate and adequate exhaust openings

- If necessary creating or enlarging exhaust openings

- Application of positive pressure at the inlet

- Verification that positive pressure ventilation is working

Positive pressure ventilation is an extremely powerful tool that can rapidly clear smoke logged areas of the building. However, if used without thinking and understanding the influence of ventilation on fire behavior, it can cause extreme fire behavior even more quickly. The following criteria should be met for safe and effective use of positive pressure ventilation:

- Firefighters understand the use of PPV and are skilled in its use

- The required tools are available

- Location and extent of the fire is known Svensson, 2000). This is not an absolute requirement, but influences the most appropriate location for the exhaust opening)

- A charged hoseline is in place for fire control (Svensson, 2000)

- Backdraft conditions are not present (Svensson, 2000; Garcia, Kauffmann, & Schelble, 2006).

- Victims or firefighters are not between the fire and the exhaust opening (Svensson, 2000)

- Victims or firefighters are not in the exhaust opening (Garcia, Kauffmann, & Schelble, 2006)

- Ventilation openings can be controlled and an adequate exhaust (preferably 2 to 3 times the size of the inlet) opening is provided (Svensson, 2000).

- Positive control of the blower (the ability to start and stop positive pressure immediately)

- Ventilation is coordinated with fire attack (Svensson, 2000; Garcia, Kauffmann, & Schelble, 2006). This requires communication with personnel at the outlet, inlet, interior working positions, and Command.

Common Problems

Kriss Garcia, co-author of Positive Pressure attack for ventilation & firefighting indicates that most situations where use of positive pressure ventilation resulted in occurrence of extreme fire behavior or some other adverse outcome generally involve one or more of the following (personal communication, May 2006):

- Lack of an exhaust opening

- Inadequate exhaust opening size

- Lack of command, control, & coordination

More to Follow

My next post will get to into the nuts and bolts of exhaust opening size and why use of positive pressure with an inadequate exhaust opening can result in extreme fire behavior.

References

Garcia, K., Kauffmann, R. & Schelble, R. (2006). Positive pressure attack for ventilation & firefighting. Tulsa, OK: Penwell.

International Fire Service Training Association (IFSTA). (2008). Essentials of firefighting (5th ed.). Stillwater, OK: Fire Protection Publications.

Kerber, S. & Madrzykowski, D. (2008).Evaluating positive pressure ventilation In large structures: school pressure and fire experiments. Retrieved May 17, 2009 from http://www.fire.nist.gov/bfrlpubs/fire08/PDF/f08016.pdf.

National Fire Protection Association (NFPA). (2006). NFPA 92A. Standard for smoke-control systems utilizing barriers and pressure differences. Quincy, MA: Author.