Fuel & Ventilation

Warning! Science Ahead

This post attempts to bring some clarity to a few scientific concepts that are often overlooked or oversimplified in fire behavior training for firefighters and fire officers. I have made an effort to make this information accessible, but not to reduce it to the point where it no longer makes sense from a scientific perspective.

Fire Power

In physics, power is the rate at which work is performed or energy expended for a given unit of time. For combustion, power is the energy released per unit of time or heat release rate (HRR). So what? Why is this important to firefighters?

It is relatively easy to describe how big a compartment or building is based on its dimensions (i.e., length, width, height) in meters (or feet). However, describing how big a fire is requires different units of measure. Likely the best way to describe the sizeĚ of a fire is on the basis of the rate at which it is releasing energy.

In Heat Release Rate: A Brief Primer, Dr. Vytenis Babrauskas observes that Heat Release Rate (HRR) is the driving force that influences many other dimensions of the fire environment. As HRR increases, temperature and the rate of temperature change both increase, accelerating fire development. In addition, increased HRR results in reduced oxygen concentration and increased production of gaseous and particulate products of incomplete combustion. For firefighters, it is also important that HRR directly relates to flow rate required for fire control.

Measuring Energy and Power

Energy is often defined as the ability to do work or cause change. Thermodynamic work is the transfer of energy from one system to another. This is sometimes, but not always accompanied by an increase in temperature (more on this in a bit).

In the United States, the traditional units of measure for energy were the British thermal unit (Btu). A Btu is the amount of energy required to raise the temperature of one pound of water from 60o F to 61o F. Adding additional Btu will continue to raise the temperature of the water until it reaches its boiling point. Changing phase from liquid to gas requires input of a large amount of energy, but there is no change in temperature!

The standard international (SI) unit for energy is the Joule (J). The joule is defined in terms of mechanical energy. However, in our context, it is useful to describe the Joule in terms of transfer of thermal energy. 4186 J will raise the temperature of 1 kilogram (kg) of water from 20o C to 21o C. For readers who are more comfortable with Btu, one Btu is equal to 1055 J (slightly more than one kilojoule (kJ)).

Power is the rate at which work is performed or energy is transferred. This necessitates a measure of the amount of energy (i.e., Btu or J) and a unit of time (generally minutes or seconds). Using traditional units, power could be described in terms of Btu/minute or Btu/second. Watts are the SI unit for power, with a Watt being a Joule/second (J/s)

To keep things simple, the remainder of this post will stick to the SI units (Joules, Watts, and oC).

Potential Energy of Fuel

Energy that is stored is known as potential energy. Fuel has chemical potential energy that is released as the fuel is oxidized in the combustion process. The energy that is released through complete combustion of a given mass of fuel is known as the heat of combustion. Heat of combustion is dependent on the chemical makeup of the fuel. Heat of combustion is usually expressed in kilojoules/gram (kJ/g) or megajoules/kilogram (MJ/kg).

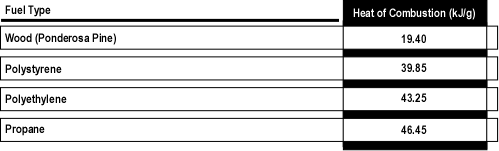

Generally (hydrocarbon based) synthetic fuels have a higher heat of combustion than cellulose fuels such as wood as illustrated in the following table:

Note: Data in this table is from the Society of Fire Protection Engineering (SFPE) Handbook of Fire Protection Engineering.

When fuel burns, the total energy that can be released is dependent on its heat of combustion and fuel mass (e.g., kg of fuel)

Heat of combustion is important, but as Dr. Babrauskas points out, the rate at which that energy is released is even more important. Heat release rate is influenced by a number of different fuel characteristics such as surface area to mass ratio, orientation (e.g., horizontal, vertical), arrangement, and geometry.

The concepts of heat of combustion and heat release rate help explain changes in the built environment that impact firefighting. Increased use of synthetic materials has increased the chemical potential energy of building materials and contents and higher heat release rates shorten time to flashover.

Oxygen and Combustion

Release of chemical potential energy from fuel depends on availability of adequate oxygen for the combustion reaction to occur. Interestingly, while the heat of combustion of various types of organic (carbon based) fuel varies widely, the amount of oxygen required for release of a given amount of energy remains remarkably consistent.

In 1917, British scientist W.M. Thornton discovered that the amount of oxygen required per unit of energy released from many common hydrocarbons and hydrocarbon derivatives is fairly constant. In the 1970’s, researchers at the National Bureau of Standards independently discovered the same thing and extended this work to include many other types of organic materials and examined both complete and incomplete combustion.

Each kilogram of oxygen used in the combustion of common organic materials results in release of 13.1 MJ of energy. This is referred to as Thornton’s Rule.

However, the concentration of oxygen in the atmosphere is only 21%. Examining the relationship between consumption of atmospheric oxygen and energy release requires adaptation of Thornton’s Rule based on oxygen concentration. Multiplying 13.1 MJ/kg of oxygen by 21% gives a value of 2.751 MJ/kg of air. The Society of Fire Protection Engineering (SFPE) Handbook of Fire Protection Engineering rounds this value to 3.0 MJ/kg of air. While it is easy to understand that air has mass, it is a bit more difficult to visualize a kilo of air! The density of dry air at sea level and at a temperature of 20o C is 1.2 kg/m3 (0.075 lbs./ft3). Air density decreases as temperature or moisture content of the air increases, but this provides a starting point for visualizing the relationship between volume and mass at normal temperature and pressure.

All this is very interesting, but how does it relate to compartment fires and firefighting?

Fuel and Ventilation

In a compartment fire, combustion occurs in an enclosure where the air available for combustion is limited by 1) the volume of the compartment and 2) ventilation.

Consider a 2.4 m x 3.7 m (8′ x 12′) compartment with a ceiling height of 2.4 m (8′). A compartment of this size has a volume of 21.312 m3 (752.63 ft3). Based on a potential heat release of 3 MJ/m3 of air, the volume of the compartment would provide sufficient air for release of 63.936 MJ. A fire burning in this compartment with a steady heat release rate of .5 MW would consume the air in the compartment in just over two minutes (127.8 seconds). However, this is an extreme oversimplification as fires generally begin with a low heat release rate and grow until they become limited by the availability of fuel or oxygen. In this case, the fire would burn for a bit longer and would then cease flaming combustion, but surface combustion may (depending on the type of fuel involved) continue for some time after the oxygen concentration drops below 15%.

It is unlikely that a fire would occur in a compartment that had no openings (or at least potential openings) such as a door and one or more windows. Even if these openings are closed, there will likely be some leakage that will influence the amount of air available to support combustion. If they are open, a substantially greater amount of air will be available to support fire growth. However, as the fire develops and a hot gas layer forms and begins to fill the compartment, exiting smoke reduces the size of the opening serving as an inlet for additional air. As this occurs, the fire becomes ventilation controlled and heat release is limited by the amount of oxygen in the air available to support combustion.

Note: Photos adapted from National Institute of Standards and Technology (NIST) ISO-Room/Living Room Flashover.

Hazard of Ventilation Controlled Fires

Many if not most fires that have progressed beyond the incipient stage when the fire department arrives are ventilation controlled. This means that the heat release rate (the fires power) is limited by the ventilation profile, in particular, the existing openings.

If ventilation is increased, either through tactical action or unplanned ventilation resulting from effects of the fire (e.g., failure of a window) or human action (e.g., exiting civilians leaving a door open), heat release rate will increase.

Ventilation is a complex strategy as it can have both positive and negative effects. Releasing smoke can make the interior environment more tenable by raising the level of the hot gas layer and removing energy and fuel (hot smoke) from the compartment or building. However, increasing the air supply to a ventilation controlled fire will increase the heat release rate, potentially resulting in a ventilation induced flashover.

It is essential that firefighters and fire officers understand the effects of tactical operations on fire behavior and coordinate their efforts to maximize the positive impact while limiting the negative consequences.

Chief Pete Lamb recently wrote a blog post titled Vent Early in which he emphasizes the need for firefighters to understand the application of ventilation strategies and to use them effectively. I suggest that we vent wisely in coordination with fire attack after considering fire behavior and building factors! Understanding compartment fire behavior and practical fire dynamics is critical to safe and effective ventilation operations.

If you found this post interesting or useful (or not), please leave a comment with your feedback.

Ed Hartin, MS, EFO, MIFireE, CFO

Tags: heat release rate, oxygen consumption principle, Tactical Ventilation, Thornton's rule

January 19th, 2009 at 19:07

Thank’s Ed, the article made sense and I found it easy to follow. Keep up the good work

June 11th, 2009 at 08:53

Ed,

Good site, just wanted to make the following correction. While you are correct that the percentage of oxygen in air is roughly 21%, this is the volumetric fraction. The actual mass fraction is roughly 23.3% (0.233). This is the number that is used to calculate the approximate heat of combustion of air. 13.1(0.233) ~ 3.0 [MJ/kg].

Regards

Rob

July 17th, 2009 at 01:33

Hi,

Interesting post. I use the Thornton’s rule for years for validating many things.

Notice that the fact windows are opened or closed, will have no change. The fire is a dynamic process and, according to Thornton, it depend on the volume of oyxgen. Even if you let your window opened, your bedroom will not increase in volume. The window affect the renewal of air, not the max amount of air available for the fire.

Some rare execption can be found when air is compressed in the room, but this is far away from the basic.

In order to use the Thornton’s rule, we must consider 2 thinks:

1) the max heat release

2) the amount of renewal of air

For the first point: in “normal” condition, a m3 of air contains 280g of oxygen. In this m3, there is only 21% of oxygen and at 14% the fire dies. So, there is only 21-14=7% of the volume availbale for combustion. As 21/3=7, this means that only 1/3 of the 280g of oxygen will be used for burning, so about 93g.

Thornton says a common fuel will release, 13460 Joules/g of oxygen. Energie for 1m3 of air is about Q=13460*93=1256000 J

If this energy is produced in one second,, we will get: P=Q/t=1256000W so 1,256MW for 1m3 of air. If we compute that with an ordinary cell height in an appartement (2,40m), we’ll get about 2,40 x 1,256 MW = 3MW for only 1m2 at ground.

But in this case, there is no fuel, because the full volume is full of air. So we must consider the fact that:

a- a part of the room is full of fuel

b- the best fuel for fast burning is smoke

Let’s imagine the neutral plane is at 1m from the ground. We have 1,256MW for each m2. Meaning a bedroom of 5mx5m (16 feets by 16 feets), will have a surface of 25m2 and produce 31,4MW which is not very far from violent flashover conditions.

Concerning point 2 (renewal of air), the problem is more complex but give use good solution, event if we don’t have “right answers”.

At the beginning of the fire, the fire always gets enought oxygen. It uses it, and uses the room as a “tank” for that. The heat increases quickly and so the O2 consumption. The window is used for renewal, but a a certain time, the renewal is lower than the consumption, as the fire use the room as a reserve tank. A bit like if you win the lotery: during a few month you’ll be able to spend more money than your salary.

But when the reserve is empty, you must lower! The fire does the same.

In fact there are 3 possibilies:

1) the renewal is good enought to let the fire increases and runs up to flashover. But, event in this case, the max HRR will depend only on the volume.

2) the renewal is very bad. In this case will die and we’ll go to backdraft conditions

3) the renewal is good but not “very good”. In this case, the fire will survive in a middle state but can’t run up to flashover. This is the opening of doors, windows (often by FF) which will cause air intake and let the fire run to flashover (vent induced flashover). But also, in this case, the max HRR will only depend on volume.

Using FDS you can validate this thrid point in a very good manner. I use it for my instructor course and when the guy see the effect of opening, comments are not needed!

This computation are usefull in order to consider the flow rate needed. Of course, if you use pulsing-penciling method, you need a low flow rate (100 to 150lpm, meaning 26 to 40gpm) in order no to produce too much vapor.

But this is only the way you can cool the gaz and attack in a under ventilated room, so in front of a small fire.

If windows fall down or if the fire is well vented, you must use a greater flow rate. But what kind of flow?

If you consider and angle of pattern of about 40 degrees, you can see a 135gpm nozzle is able to flow water on a surface of about 6mx6m, not more. For covering more, you must narrowed the pattern, and you loose in contact between heat and water.

A 6×6 room can produce 6x6x1,256MW = 45MW

A liter of water can absord about 2,6MW but this is true only if 100% is used. If you have a 80% transformation, that’s good. So you flow one liter and “suck” only 80% of 2,6MW = 2,08MW

For a 45MW fire in your room, you’ll need to flow at 45/2,08 = 21,6 liters per second, so 57 gallons per second. A nozzle at 500lpm as we use in Europe, is 135gpm. It flow only 8,33 liter per second. Ho…. ūüôĀ

Yes, but in one second, you can’t cover the full surface of the room. With three nozzle, in static position, that’s possible: 3×8,33 = 25 liters per second, and that’s good. In reality we will use the movement of the nozzle and inertia of flame to cover the whole room. In three seconds, we’ll be able not to kill completly the fire, but to kill it enought to win. This is combination attack used a Z, O or T pattern. The Z is for large room as it flow more water that the O which is for medium room, and T is for smaller one.

This mean two thinks:

1) we must consider learning 2 methods of attack. One for under ventilated fire, without vapor production (pulsing-penciling), and one for well ventilated fire (combination attack), in a “violent” way, flowing a great amount of water in a very short time. In this case, the opening are bad think as they let the fire increase, but are also a good think as they will let the excess of vapor getting outside rather than burning us.

2)we must always get nozzle flowing 135gpm and consider that in case of glass breakage, this will let us strike at maximum against a 40m2 fire (about 400 feet square). In front of a larger room, nozzle must be bigger.

Best regards to you all

PL Lamballais

http://www.flashover.fr

October 31st, 2009 at 12:33

[…] Thorntonís Rule specifies that one kilogram (1 kg) of oxygen is required to release 13.1 mega joules (MJ) of energy. Multiplying 13.1 MJ/kg of oxygen by 21% (the concentration of oxygen in air) provides a value of 2.751 MJ/kg of air. The Society of Fire Protection Engineering (SFPE) Handbook of Fire Protection Engineering (SFPE, 2002) rounds this value to 3.0 MJ/kg of air. For a more detailed discussion of Thorntonís Rule and the relationship between fuel, oxygen, and energy release, see Fuel and Ventilation. […]

February 8th, 2010 at 10:26

I haven’t read the other comments, but when you calculate Thornton’s Rule with respect to kgair, you use the molar percentage of air instead of the mass percentage of air, which seems more applicable – giving about 3.1 MJ/kg.

(13100 kJ/kgO2)(n*MW_O2)/(n*MW_air) = (13100 kJ/kgO2)(1*16.00*2 kgO2)/(1*16.00*2+3.76*14.01*2 kgair) = 3.1 MJ/kgair

I could have made a mistake, though.

May 30th, 2013 at 09:30

[…] For many firefighters, door entry is simply a process of remembering to “try before you pry” and then figuring out how to force the door if it is locked. For others it is simply kicking the door in! Often overlooked is the fact that the entry point is a ventilation opening; sometimes an inlet, sometimes an outlet, and often both. When the fire is ventilation controlled, opening the door and increasing air flow to the fire will result in increased heat release rate. Depending on the stage of fire development and conditions within the compartment or structure, this may result in extreme fire behavior such as a ventilation induced flashover or backdraft (see Fuel & Ventilation). […]

November 7th, 2013 at 13:59

Ed,

Been looking for a good summary of this topic to give me a simple overview, lots of Phd’s out there with lots of equations, this made a lot more sense and even gives a simple example for me to work through – i don’t need accurancy to 1/1000th of a percent,just some good common sense – metric units too, real bonus.

Thanks

Lee