Under Pressure

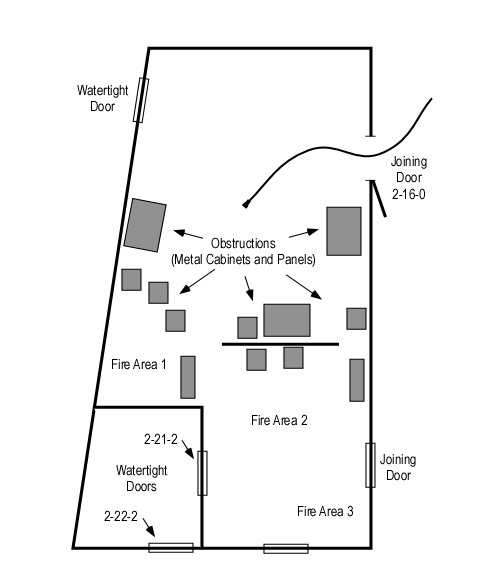

Tuesday, November 17th, 2009Understanding how to develop fire streams has been critical since firefighters began to use hose and nozzles (Figure 1) to increase the effectiveness and efficiency of firefighting operations.

Figure 1. In the Beginning!

When selecting handline nozzles, firefighters and fire officers generally consider four nozzle characteristics: 1) type of nozzle (combination or solid stream/smoothbore), 2) fixed or variable flow, 3) flow rate, and 4) designed operating pressure. Saving the big debate regarding combination and solid stream/smoothbore nozzles for another post, this post will focus primarily on nozzle pressure and flow rate.

Nozzle Function

A little over 20 years ago I was asked an interesting question by a newly hired recruit firefighter. She had no prior fire service experience and was puzzled by the hose evolutions being taught during her academy. As I attempted to help her make sense of these alien concepts, she finally asked “What’s the pump for? Why don’t we just put the nozzle on the end of the hose from the hydrant?” Her instructors may have assumed that hydraulics was a topic for apparatus operators or that everyone understood the basic concepts involved in developing an effective fire stream.

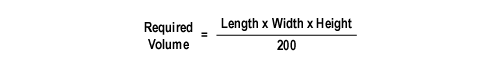

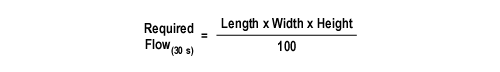

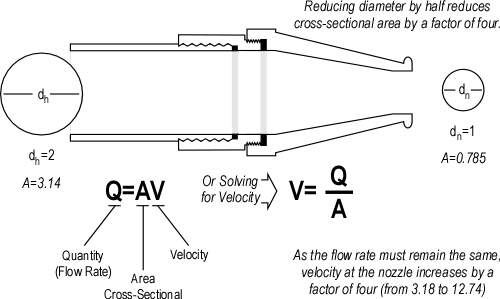

The primary function of a nozzle is to increase the velocity of water flowing from the hoseline. A fire stream must have sufficient velocity for water to reach from the nozzle to the intended target. The simple equation illustrated in Figure 2 is essential to understanding nozzle design and performance. Flow rate (the quantity of water) from a nozzle is dependent on the area of the opening and the velocity of the water being discharged (for a given size opening, the greater the velocity the higher the flow rate).

Figure 2. Important Equation

As indicated in the equation Q=AV, flow rate is related to velocity and the size (area) of the nozzle orifice. This relationship is simple to understand when looking at solid stream/smoothbore nozzles. Nozzle pressure translates to velocity at the tip. For a given size tip, increasing nozzle pressure increases velocity and thus the flow rate from the tip. For example, a 1-1/4” (32 mm) tip will flow 317 gpm (1200 lpm) at 50 psi (345 kPa). Increasing the nozzle pressure to 80 psi (552 kPa) increases the flow rate to 401 gpm (1518 lpm). Flow rate can be varied by changing the size of the tip, the nozzle pressure, or both.

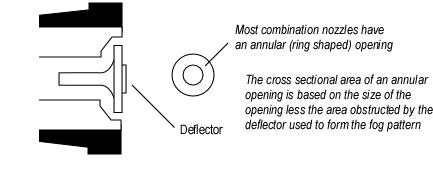

Visualizing nozzle orifice size is a bit more difficult with combination nozzles. Most combination nozzles use a deflection stem (see Figure 3) to form the fog pattern. The nozzle orifice is an annular (ring shaped) space between the deflector and the body of the nozzle tip.

Figure 3. Combination Nozzle Orifice

The change in direction at the deflection plate results in formation of small droplets of water. Nozzles may also have fixed teeth or a spinning, toothed turbine to aid in the production of appropriate sized droplets as water leaves the nozzle.

Nozzle Pressure and Droplet Size

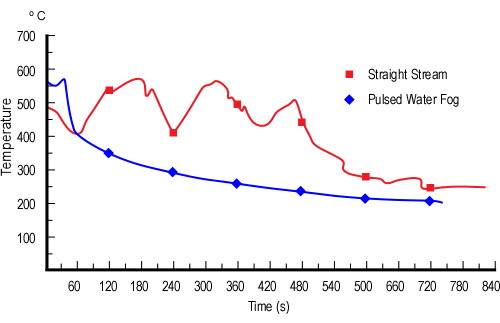

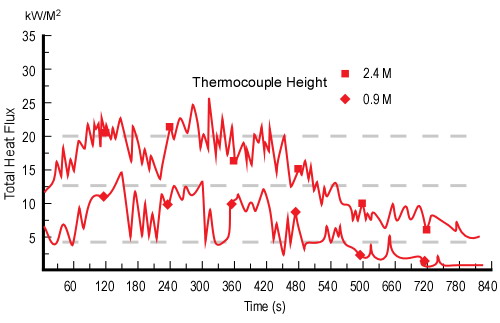

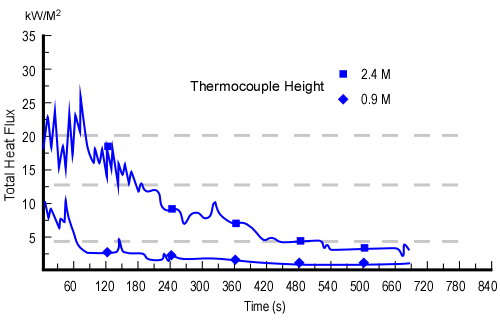

Water is an excellent extinguishing agent because it has a high specific heat (energy required to raise its temperature) and high latent heat of vaporization (energy required to change it from water to steam). Of these two factors, conversion of water to steam is most significant as it absorbs 7.5 times more energy than heating water from 20o C (68o) to its boiling point. The firefighters’ power is not simply related to flow rate, but flow rate effectively applied to transfer heat from hot gases and surfaces by changing its phase from liquid (water) to gas (steam). Extinguishing a compartment fire generally involves converting a sufficient flow (gpm or lpm) of water to steam. So while the “steam” itself does not generally extinguish the fire, the energy absorbed in turning the water to steam has the greatest impact on fire extinguishment

Where the water is vaporized into steam depends on the method of fire control being used (direct attack, indirect attack, or 3D gas cooling). In direct attack water is vaporized on burning and pyrolyzing fuel surfaces to slow and stop the process of pyrolysis. Water is also vaporized on contact with hot surfaces in an indirect attack, but in this case the purpose is to produce a sufficient volume of steam to fill the compartment, achieving fire control or mitigating potential for extreme fire behavior such as a backdraft. Gas cooling on the other hand requires that the majority of the water be vaporized in the hot gas layer. This cools the hot gases (fuel) overhead, providing buffer zone and safer work environment for firefighters. It is important to remember that gas cooling is not an extinguishing technique, but merely one tool in controlling the fire environment.

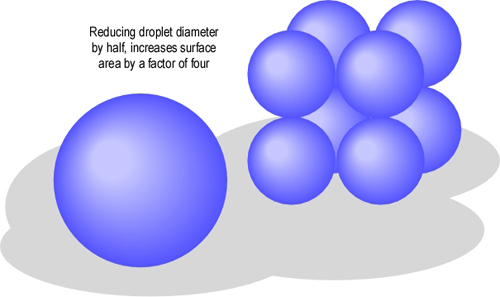

Heat moves from objects of higher temperature to objects of lower temperature until temperature equalizes. Key factors in the speed of heat transfer are the difference in temperature and surface area of the materials. In the fire environment, burning fuel, nearby surfaces, and hot gases are considerably higher temperature than the water used for fire control and extinguishment. Surface area of the water in contact with the material being cooled is extremely significant in determining the speed of heat transfer. A larger surface area in relation to the amount of water will result in faster heat transfer and more rapid cooling.

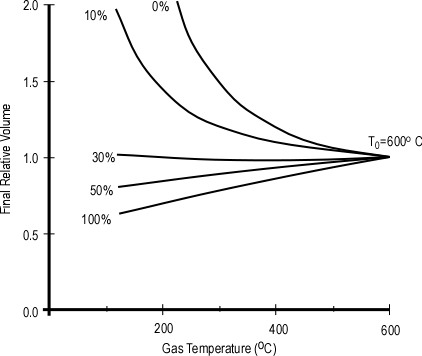

If the volume of water remains the same, reducing droplet size increases surface area substantially. For example if droplet size is reduced by half, surface area increases by a factor of four (see Figure 4).

Figure 4. Droplet Diameter and Surface Area

Note. Adapted from Water and Other Extinguishing Agents (p. 194) by Stefan Särdqvist, 2002, Karlstad, Sweden: Raddningsverket. Copyright 2002 by Stefan Särdqvist and the Swedish Rescue Services Agency

Increased surface area increases heat transfer as droplets travel through the hot gas layer, rapidly reducing temperature. However, the down side of smaller droplets is that they do not travel as far and may not be able to penetrate a large distance in an extremely hot environment, making a fog pattern with small droplets potentially less effective in direct attack or when working in an extremely large compartment. Fortunately, when a fog pattern is adjusted to a straight stream much (but not necessarily all) of this problem is overcome.

What does nozzle pressure have to do with droplet size? Nozzles do not produce uniform droplet sizes. The fog pattern developed by a typical combination nozzle produces a mix of small and larger droplets. However, average droplet size and the percentage of droplets that are 0.3 mm (0.012”) in diameter is dependent on both nozzle design and pressure. However, for any nozzle design, increased nozzle pressure will result in smaller droplets.

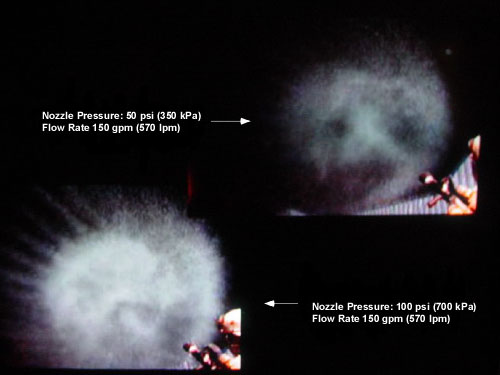

Gresham Fire & Emergency Services conducted a series of qualitative tests on droplet size produced by the Task Force Tips Dual-Pressure Mid-Force Nozzle operating at 50 psi (345 kPa) and 100 psi (689 kPa). Droplet size was assessed by examining hang time, the time which droplets remained suspended in the air after a short pulse of water fog (smaller droplets remain suspended for a longer time while large droplets fall to the ground more quickly). Results of this test were captured on video and synched to ensure that the visual comparison was at the same time after the nozzle was closed. As illustrated in Figure 5, with the same flow rate, the nozzle pressure of 50 psi (345 kPa) resulted in larger droplets than a nozzle pressure of 100 psi (689 kPa).

Figure 5.

Nozzles operating at a lower pressure will have larger droplet size. This does not impact substantially on direct attack, but can have a significant impact on the effectiveness and efficiency of these nozzles when used for gas cooling. This does not mean that they cannot be used! It simply means that they will be less effective and are likely to result in less efficient vaporization of water (more water will end up on the floor).

Impact on Operations

While it is important to understand the underlying principles related to nozzle design and performance, it is even more important to understand the impact of these concepts on firefighting operations. The next post in this series will examine the concepts of efficiency and effectiveness in greater depth and why effective cooling capacity may be more important than simply looking at flow rate.

Ed Hartin, MS, EFO, MIFireE, CFO

References

Särdqvist, S. (2002). Water and other extinguishing agents. Karlstad, Sweden: Raddningsverket (Swedish Rescue Services Agency).

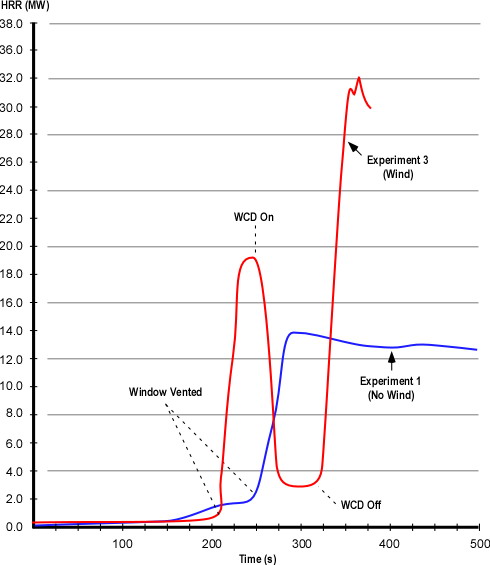

Note: Adapted from Firefighting Tactics Under Wind Driven Conditions.

Note: Adapted from Firefighting Tactics Under Wind Driven Conditions.