Estimating Required Fire Flow:

The Iowa Formula

Thursday, January 8th, 2009

As discussed in Estimating Required Fire Flow: The National Fire Academy Formula, there are a number of ways to estimate required (total) fire flow or tactical rate of flow (required for fire attack). This post examines the groundbreaking work of Keith Royer’s and Floyd W. (Bill) Nelson’s work in development of a method to identify the volume and flow of water necessary for fire control with water fog.

The fire service often accepts (or rejects) concepts, theories, and practices based on what is written in training manuals, trade magazines, or presented by well known speakers. Others take the message and pass it along, trying to improve or simplify the message. Much can be lost in the translation. While we are strongly influenced by tradition, we occasionally forget history, and valuable work that was done by our predecessors is forgotten or misinterpreted. This is particularly true in the case with regard to Royer’s and Nelson’s volume and rate of flow formulas.

Origins of the Iowa Formula

In 1951, Keith Royer and Floyd W. (Bill) Nelson were hired by Iowa State University to manage the Engineering Extension Service Firemanship Training Program. Royer and Nelson both became involved in the Exploratory Committee on the Application of Water, a research team comprised of fire service, fire protection engineering, and fire insurance representatives. The principal work of the Exploratory Committee was investigation of the use of water fog for firefighting.

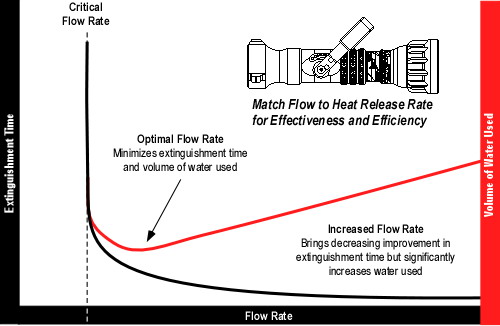

One critical question faced by Royer and Nelson was how much water was necessary to control a fire with water fog? In his book Qualitative Fire Behavior (1989), Nelson observed: “In principle, firefighting is very simple. All one needs to do is put the right amount of water in the right place and the fire is controlled.” Royer and Nelson recognized that heat release from the fire must be balanced by the energy required to heat water to its boiling point and change it to steam. Through their research, they discovered that too little or too much water was considerably less effective than the right amount.

Note: While math is considerably simpler when using standard international (SI) units, Royer and Nelson did their work in traditional units (e.g., feet, gallons, British thermal units, degrees Fahrenheit). For now, I will stick with traditional units to illustrate how the Iowa Formula was developed. Safe and Effective Use of Fog Nozzles: Research and Practice (Wiseman & Bertrand, 2003) includes adaptation of the formula to the use of SI units.

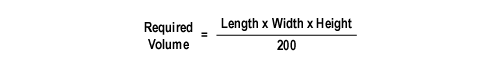

Based on the results of their research on extinguishing compartment fires, Royer and Nelson developed the following formula to determine the volume of water (in gallons) required to control a fire in a given size compartment.

Royer and Nelson based this formula on the following two concepts:

- Water converted to steam expands at a ratio of 1700:1, as a result one gallon of water (0.13 ft3) produces 221 ft3 of steam. However, in practical application it is unlikely that all of the water would be converted to steam. Royer and Nelson estimated the efficiency of this conversion at 90%, resulting in production of 198.9 ft3 of steam per gallon. They rounded this value to 200 to simplify calculation.

- In 1955 the Factory Mutual Laboratories determined that oxidization of ordinary fuel with 1 ft3 of oxygen (at standard temperature and pressure) resulted in release of 535 British thermal units (Btu) of energy. Based on an atmospheric oxygen concentration of 21% and substantive reduction or cessation of flaming combustion at 15% concentration, Royer and Nelson estimated that seven percent (of atmospheric concentration of oxygen) was available to support flaming combustion. This led them to estimate that combustion of ordinary fuel with 1 ft3 of air would result in release of 37 Btu. Combustion of ordinary fuel with 200 ft3 of air (would therefore release 7,400 Btu. One gallon of water, raised from a temperature of 62o F to 212o F and completely converted to steam will absorb 9330 Btu. As with their calculation for steam production, an efficiency factor of 90% can be applied, resulting in absorption of 8397 Btu. This illustrates that a single gallon of water converted to steam will absorb the energy released by combustion of ordinary fuel with 200 ft3 of air.

Note: There are a few problems in using volume when discussing the energy released based on the quantity of oxygen or air in the combustion reaction. Chief of which is the variation in volume based on temperature. It would be more appropriate to speak to the mass of oxygen or air. However, Royer and Nelson based their approach on volume, so we will follow this line of reasoning (recognizing that while it is simple to understand, it has significant limitations).

Royer and Nelson used these concepts to support their formula to determine the volume of water required to control a fire with water fog.

Volume and Flow Rate

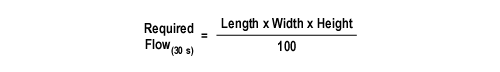

The volume formula, while a good start, still did not identify the required flow rate. The required volume could be delivered over various periods of time and still control the fire. If water was applied over a one minute period, the volume formula could be used to determine flow rate directly. However, Royer and Nelson estimated if water was applied in the right place, most fires could be controlled (but not necessarily extinguished) with water fog in less than 30 seconds. Given this timeframe, the volume formula translated into the rate of flow formula as follows:

Limitations

The Iowa Rate of Flow Formula is designed to estimate the flow rate required to control a fire in a single open area of a building with a 30 second application of water fog. This approach requires foreknowledge of the building and made the Iowa rate of flow formula most suited for preplanning, rather than tactical application.

That said, this does not mean that you cannot apply this formula (or its concepts) tactically based on the estimated area of involvement in a building that has limited compartmentation (e.g., multiple, interconnected compartments, open doors, unprotected shafts). However, it is essential to remember that Royer and Nelson based their formula on a 30 second application (potentially from multiple points) outside the compartment, and not working your way from compartment to compartment as is typically done in offensive, interior firefighting operations.

Additional Considerations

The concept that water applied to the fire compartment will turn to steam and fill the space, displacing air and hot smoke is a foundational principle of the indirect and combination attack as discussed by Lloyd Layman, Keith, Royer and Bill Nelson. This physical reaction is also commonly accepted as fact within the fire service. However, the science is a bit more complicated.

Royer and Nelson are correct in assuming that at its boiling point water converted to steam will expand 1700 times and not increase in temperature. However, water converted to steam while passing through the hot gas layer does not increase the total volume of gas and vapor in the space. The expansion of steam is more than counterbalanced by contraction of the hot gas layer due to cooling. On the other hand, water that passes through the hot gas layer (without taking energy from the gases) and converts to steam on contact with compartment linings (walls, ceiling) results in addition of the volume of steam to the volume of air and smoke in the compartment. This is not commonly understood and will be the subject of a later post. Steam formed at 212o F (100o C) can continue to absorb energy if the temperature of the fire environment is above 212o F (100o C) and will continue to expand (while the hot gases correspondingly contract).

One of the fundamental assumptions central to the Iowa formula is that the oxygen available to the fire is limited to that contained within the volume of the fire compartment. However, this is unlikely. If smoke is visible, ventilation (i.e., exchange of the atmosphere in the compartment with outside air) is taking place to some extent. In addition, if the compartment is not totally isolated from the remainder of the building, air track (movement of smoke and air) will provide additional oxygen to the fire. However, Royer and Nelson did identify an extremely important and often overlooked point. The Iowa tests showed that the heat release rate from actual compartment fires was less than the value based on the potential heat release from the fuel involved due to limitations in ventilation.

In a compartment fire, heat release rate is often (except in the incipient and early growth stage) limited by ventilation. One of the most important lessons that can be learned from Royer’s and Nelson’s work is that the flow rate and volume of water required for fire control is related not only to the method of attack, but also to the ventilation profile of the compartment or building involved.

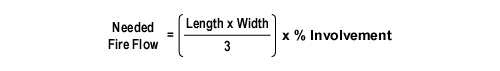

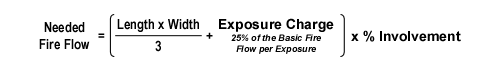

Building on the Past

The National Fire Academy Fire Flow Formula (see Estimating Required Fire Flow: The National Fire Academy Formula) is based on synthesis of the experience of a group of experienced fire officers. On the other hand, the Iowa Formula is based on analysis of extensive empirical evidence developed during live fire tests. These formula each have different assumptions and are designed for different purposes. However, both provide useful information if they are used as intended. Future posts will examine the topic of fire flow from an international perspective, looking at the approaches taken by Cliff Barnett from New Zealand and my colleague Paul Grimwood from the United Kingdom.

For more information on Fire Flow, visit Paul Grimwood’s website www.fire-flows.com. Paul has amassed a tremendous amount of information on this topic from around the world.

Ed Hartin, MS, EFO, MIFireE, CFO