Choose Your Weapon: Part 1

Fire Stream Effectiveness & Efficiency

Nozzle Pressure

In my previous post It’s the GPM¯ I discussed the importance of matching flow rate to tactical application. This post was in part a response to LT Bob Shovald’s article Improving Preconnect Function and Operation which was published in the October issue of Fire Engineering magazine. More recently, I read an article by FF Armand Guzzi on Firehouse.com titled Analysis of Effective Fire Streams-Part I. Both LT Shovald and FF Guzzi advocate the use of low-pressure, high flow nozzles on 1-3/4″ (45 mm) hoselines based in large part on the reduction in nozzle reaction when compared with a nozzle operating at the same flow rate with 100 psi (700 kpa) nozzle pressure.

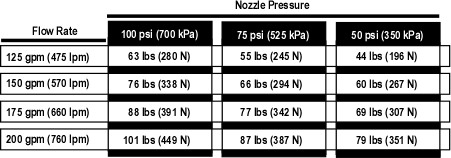

I have no argument with LT Shovald’s and FF Guzzi’s observation that lower nozzle pressure makes handlines easier to handle. As illustrated below the nozzle reaction from combination nozzles set for a straight stream pattern have considerably less nozzle reaction at 75 psi (525 kpa) or 50 psi (350 kpa) than at 100 psi (700 kpa).

As the preceding table illustrates, lowering nozzle pressure from 100 psi (700 kpa) to 75 psi (525 kpa) reduces the force of nozzle reaction by roughly 16%. If nozzle pressure is reduced further to 50 psi (350 kpa), nozzle reaction is reduced by approximately 24%.

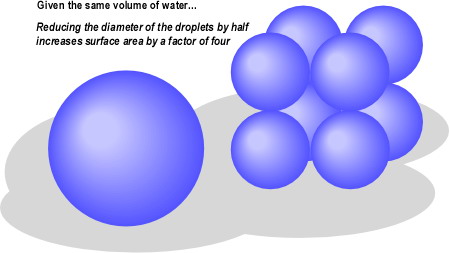

However there are other consequences of lower nozzle pressure. Lower nozzle pressure increases potential for kinking. This can to some extent be addressed through good hose handling, but if kinks are not removed, flow rate is reduced. Lower nozzle pressure also results in larger droplet diameter. What difference does that make? As discussed in It’s the GPM, conversion of water into steam is what does the majority of the work in fire control. A given volume of water in large droplets has less surface area than the same volume of water in smaller droplets as illustrated below.

When applying water in a direct attack, water is used to cool surfaces and the principal concern is that the stream has sufficient reach and penetration to get to the intended surface. In this application, droplet size has limited effect, since the objective is to put water directly on the burning fuel or hot surface and develop a thin film. A thin film of water will quickly convert to steam, taking energy away from the fuel surface, reducing pyrolysis and achieving extinguishment or cooling the unignited surface.

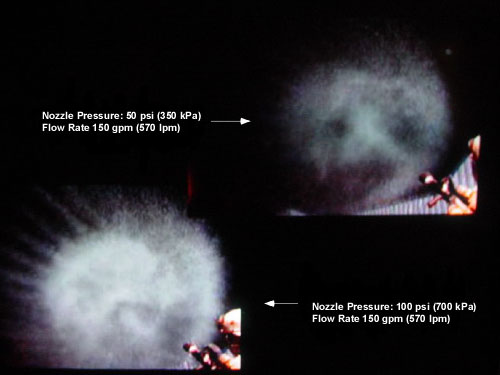

However, when water is used to cool the hot gas layer, droplet diameter is extremely important. Droplets must be large enough to have sufficient reach, but be small enough to vaporize while passing through the hot gas layer. Large droplets will either pass through the hot gas layer vaporizing on contact with compartment linings (resulting in excessive steam production) or falling out of the hot gas layer before vaporizing. The following photos illustrate application of a short pulse at a flow rate of 150 gpm (568 lpm) at both 50 psi (350 kpa) and 100 psi (700 kpa).

Effectiveness & Efficiency

How exactly do effectiveness and efficiency apply to hoseline operation and fire streams? An action is effective when it is adequate to accomplish a purpose; producing the intended or expected result. It is efficient when performing or functioning in the best possible manner with the least waste of time and effort. An effective fire stream quickly accomplishes the task at hand, whether this is controlling the fire through direct or indirect attack, cooling hot gases overhead, or cooling exposed, but unignited surfaces. An efficient fire stream absorbs the greatest amount of energy with the lowest volume of water.

As applied to hoseline deployment, effectiveness and efficiency of application are dependent on the hoseline being quickly stretched to the appropriate location for water application.

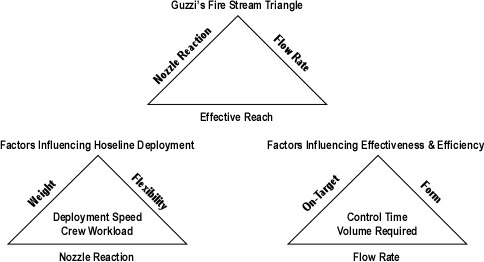

Hoseline deployment and water application must be effective and efficient. However, Guzzi’s fire stream triangle, confounds these concepts and misses several key influencing factors. The following graphic disentangles these concepts and expands on Guzzi’s simple graphic representation.

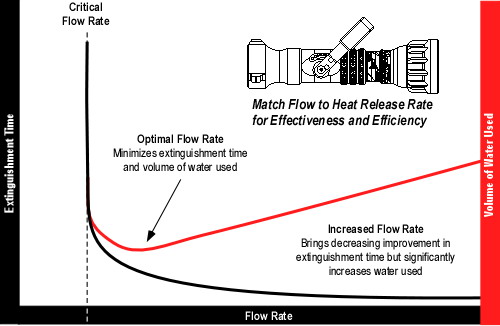

While water application must exceed the critical rate of flow, continuing to increase flow rate brings diminishing returns (in fire control speed) while increasing the total volume of water use discussed in It’s the GPM.

Maximizing both effectiveness and efficiency requires a handline with high flow capability with a nozzle that can be used to adjust the flow rate based on conditions and the task at hand. Both automatic and variable flow nozzles provide this capability.

Discussion of fire stream effectiveness and efficiency will continue in my next post with an examination of nozzle selection considerations.

Ed Hartin, MS, EFO, MIFireE, CFO

July 5th, 2009 at 07:49

[…] Choose Your Weapon: Part 1 Fire Stream Effectiveness & Efficiency Criticism Versus Critical Thinking […]