It’s the GPM!

Thursday, November 6th, 2008I recently read an article in the October issue ofFire Engineering magazine titled Improving Preconnect Function and Operation. The author, LT Bob Shovald, described how his department approached the process of improving operations with small, preconnected handlines and focused on three critical factors in effective engine company operations: 1) Hose diameter and flow rate, 2) nozzle selection, and 3) hoseloads. LT Shovald made a number of good points, but misconnected on the basic science behind effective and efficient use of water for fire control.

Flow Rate

LT Shovald makes a case for high flow handlines based on changes in the built environment that influence potential fire behavior.

Primarily it comes down to one important factor, gallons per minute (gpm). Using 95- and 125-gpm attack lines is outdated and dangerous.

- Because of the huge increase of synthetic materials in modern homes and businesses, including foams, plastics, vinyl, and volatile coatings, we are now experiencing fires with higher rates of release than ever before.

- Because of the high cost of energy, more homes and businesses have improved insulation. In a fire, this seals that increased heat inside the structure.

- As a result of more effective fire prevention programs, we arrive on-scene much sooner than in years past, in large part thanks to inexpensive smoke detectors.

What this adds up to is that we are getting on-scene sooner to hotter, more aggressive fires, often just before flashover conditions or self-ventilation. To fight the beast, today we need a bigger gun with bigger bullets (i.e., proving the greater gpm and thus more water faster at the start of our interior attacks). The gpm not the pressure and not the steam kill the beast.

LT Shovald’s argument for high flow handlines sounds reasonable. However, there are a few problems once you look past the surface.

Fire Power vs. Firefighting Power

LT Shovald correctly makes the connection between heat release rate and flow rate necessary for fire control. All too often, firefighters think that it takes “gpm to overcome Btu”. However, British thermal units (Btu) like Joules (J), are a measure of energy, not its release rate. Heat release rate is expressed in units of energy per unit of time, such as Btu/minute or watts (J/s).

Heat release rate is the most critical factor compartment fire development. If heat release rate is insufficient (e.g., a small fire in a metal trash can) the fire will not flashover or reach the fully developed stage. On the other hand, if the fire involves a recliner or couch, heat release rate is likely to be sufficient for the fire to grow and rapidly transition through flashover to the fully developed stage.

However, there is another critical factor in this scenario. Oxygen is required for the fire to release the chemical potential energy in the fuel. If doors are closed and windows are intact, the fire may quickly consume much of the available oxygen. If this occurs, heat release rate is limited by ventilation and fire growth slows.

LT Shovald states that “it’s the gpm, not the pressure, and not the steam” that extinguishes the fire. Flow rate is critical, but this is not entirely correct. Water is an excellent extinguishing agent because it has a high specific heat (energy required to raise its temperature) and high latent heat of vaporization (energy required to change it from water to steam). Of these two factors, conversion of water to steam is most significant as it absorbs 7.5 times more energy than heating water from 20o C ( 68o F) to its boiling point. The firefighters power is not simply related to flow rate, but flow rate effectively applied to transfer heat from hot gases and surfaces by changing its phase from liquid (water) to gas (steam). Extinguishing a compartment fire generally involves converting a sufficient flow (gpm or lpm) of water to steam. So while the “steam” itself does not generally extinguish the fire, the energy absorbed in turning the water to steam has the greatest impact on fire extinguishment.

Changes in the Built Environment

LT Shovald is correct that many of the synthetic fuels used in today’s buildings have a higher heat of combustion (potential chemical energy) and given sufficient ventilation have a higher heat release rate when compared to materials such as wood and paper. True to their design, modern, energy efficient buildings retain energy during fire development, speeding the process. However, this type of building also controls normal ventilation (the building is not as βleakyβ as older structures) and energy efficient windows are far less likely to fail and change the ventilation profile. As a consequence, the fire department is likely to encounter ventilation controlled fires where heat release rate is limited by the available oxygen. Early detection may also influence fire conditions as firefighters may arrive to find a pre-flashover growth stage fire when heat release has not yet peaked.

The key here is that flow rate must be sufficient to meet or exceed the fires heat release rate. Arriving earlier in the fires growth and building characteristics leading to a ventilation controlled fire, do not necessarily lead to the need for a higher flow rate, on the contrary, the required flow rate during the growth stage is actually lower than that for a fully developed fire (when heat release rate is at its maximum). However, firefighters must also consider potential increase in heat release rate that result from tactical ventilation or unplanned changes in the ventilation profile (e.g., failure of a window).

One excellent point in supporting the argument for high flow handlines that LT Shovald did not raise is the large volume (floor area and ceiling height) and limited compartmentation encountered in many contemporary homes. Older homes generally had smaller rooms and were more highly compartmented. Many new homes have spacious and open floor plans, in some cases with multi-level atriums and high ceilings. In addition to frequently having open floor plans, many of these buildings are also have an extremely large floor area. This type of structure presents a significantly different fire problem and often requires a much higher flow rate than a more traditional, highly compartmented residence.

Tactical Flow Rate

While I agree with LT Shovald regarding the value of high flow handlines, his statement that 95 and 125 gpm are “outdated and dangerous” is unsupported. Safe, effective and efficient fire control requires:

- Water application to control the fire environment as well as direct attack on the fire

- Appropriate flow rate for the tactical application (cooling hot, but unignited gases may be accomplished at a lower flow rate than direct attack on the fire)

- Direct attack to exceed the critical flow rate based on the fires heat release rate

- Sufficient reserve (flow rate) be available to control potential increases in heat release rate that may result from changes in ventilation

- Water application in a form appropriate to cool its intended target (i.e., small droplets to cool hot gases or to cover hot surfaces with a thin film of water).

- Water to reach its intended target (fog stream to place water into the hot gas layer and a straight or solid stream to pass through hot gases and flames and reach hot surfaces)

- Control of the fire without excessive use of water

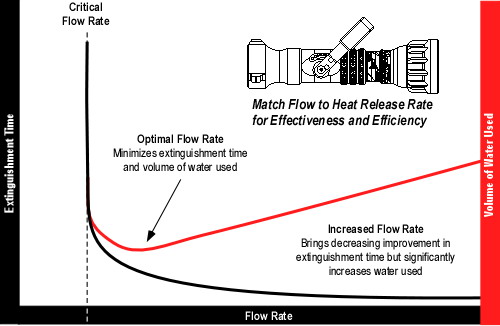

A flow rate of 95 or 125 gpm is only dangerous if firefighters attempt to use it to control a fire which requires (or has the potential to require) a higher flow rate. While a high flow rate will quickly extinguish a small fire, this generally results in use of considerably more water as illustrated below.

Effective and efficient fire control requires that we match the flow rate to the task at hand. At the simplest level this means using 1 ½” (38 mm) or 1 Ύ” (45 mm) handlines for smaller fires and 2″ (50 mm) or 2 ½” (64 mm) handlines for larger fires. It may also mean placing control of flow rate in the nozzle operators hands by using a variable flow or automatic nozzle and letting the firefighter select the flow rate based on the tactical situation.

Ed Hartin, MS, EFO, MIFireE, CFO