Choose Your Weapon: Part 2

Fire Stream Effectiveness & Efficiency

This post continues my examination of fire stream effectiveness and efficiency with a look at factors influencing nozzle selection and a recap of factors influencing the effectiveness and efficiency of fire streams.

LT Bob Shovald’s article Improving Preconnect Function and Operation in the October issue of Fire Engineering magazine and FF Armand Guzzi’s article Analysis of Effective Fire Streams-Part I published on Firehouse.com advocated the use of high flow handlines equipped with low pressure nozzles. As pointed out in my previous posts It’s the GPM¯ and Choose Your Weapon: Part I, flow rate is critical and nozzle reaction is an important consideration, but there is a bit more to this puzzle.

Nozzle Selection

In the conclusion of his article, FF Guzzi states that “nozzle reaction should be a primary factor in determining what flows are needed by the department” [emphasis added]. I disagree. Heat release rate of the fire determines what flow rate is required. Nozzle reaction is one factor in determining the flow rate that a particular crew can deliver.

LT Shovald and FF Guzzi place a high priority on low nozzle reaction in the selection of low pressure nozzles for handline operations. However, when gas cooling is used to address the three dimensional threat presented by the hot gas layer in a compartment fire, low pressure nozzles are considerably less effective and efficient than those using a higher pressure. As illustrated in the following photo, use of nozzles having a 100 psi (700 kPa) nozzle pressure results in small droplets (0.3 mm average diameter) that have excellent hang time allowing effective cooling of the hot gas layer.

Croatian Firefighters Practice Gas Cooling Nozzle Technique

In addition, when adjusted to straight stream, these nozzles also provide effective penetration and reach within the context of offensive, interior firefighting operations.

Good hose handling skills and nozzle technique allow a two person crew to work effectively with 1-3/4″¯ (45 mm) to 2″¯ (50 mm) handlines with flow rates up to 200 gpm (760 lpm) for offensive, interior firefighting operations (even with a nozzle pressure of 100 psi (700 kPa)). However, the flow rate required is often less than the upper end of the flow range. For example, when working in a compartmented residential fire, effective cooling of the hot gas layer can frequently be quite effectively accomplished with of a flow of 30 gpm (115 lpm) to 60 gpm (230 lpm). How can we address these diverse flow requirements during firefighting operations?

Both variable flow and automatic nozzles can be used effectively to adjust flow rate based on tactical requirements. However, this task is accomplished through somewhat different methods.

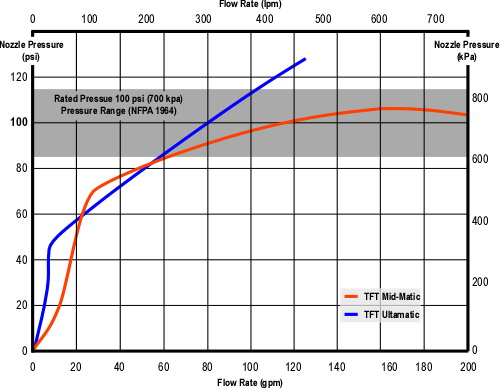

Automatic Nozzle: An automatic nozzle varies flow through a specified range using a variable orifice controlled by a spring to maintain nozzle pressure in a narrow range. For example, a nozzle such as the Task Force Tips mid-force nozzle has a flow range of 70 gpm (265 lpm) to 200 gpm (760 lpm). At 70 gpm (265 lpm) the nozzle pressure is approximately 85 psi (593 kPa). As flow increases towards the upper end of the flow range, the orifice size becomes larger and nozzle pressure increases slightly. For example, at a nozzle pressure of approximately 110 psi (758 kPa) the TFT mid-force nozzle reaches its maximum designed flow of 200 gpm (760 lpm). The apparatus operator determines the maximum flow rate by setting the line pressure at the pump. The nozzle operator can achieve that flow rate by opening the nozzle fully or can use a lower flow rate (while still maintaining correct nozzle pressure) by only opening the nozzle part way.

TFT Mid-Force Nozzle Pressure and Flow Rate

However, as illustrated in the preceding graph, the nozzle pressure at the lower end of the flow range is lower (with resulting larger droplet size). Performance of automatic nozzles is best when the nozzle pressure is at or above 100 psi.

Variable Flow Nozzle: Variable flow nozzles also have a variable size orifice. However, with this type of nozzle changes in orifice size must be made manually. Most users don’t change the flow rate. However, pumping the line for the maximum desired flow and then reducing flow rate at the nozzle provides an excellent performance. Unlike the automatic, nozzle pressure does not remain the same when flow rate is reduced. Reducing flow rate while maintaining the same discharge pressure increases nozzle pressure. However, as flow rate is reduced, nozzle reaction does not increase (and in many cases is substantially less). This is because nozzle reaction is influenced to a far greater extent by flow rate than nozzle pressure. The other advantage of using this approach to flow control is that the lower flow rate (usually used for gas cooling) at higher nozzle pressure produces extremely small droplets which are highly efficient at absorbing energy in the hot gas layer. On the down side, variable flow nozzles are slightly more complex to operate as there is a separate control for flow rate.

Things to Think About

Selection of hoseline diameter and nozzle design involves consideration of multiple factors. Each fire department must consider their particular circumstances in making these decisions. Remember that there is more than one way to safely and effectively achieve fire control. As Sir Eyre Massey Shaw, first chief of the Metropolitan London Fire Brigade observed in 1876:

From the remotest periods of antiquity to the present time, the business of extinguishing fires has attracted a certain amount of attention; but is a most curious fact that, even now, there is so little method in it in that it is a very rare circumstance to find any two countries, or even any to cities in one country, adopting the same means, or calling their appliances by the same name.

It is essential that firefighters and fire officers understand both fire dynamics and the tools of their craft. When evaluating effectiveness and efficiency, keep the following key points in mind:

- Each type of nozzle has different performance characteristics and will perform well under specific conditions and less optimally under others.

- No single nozzle will perform well under all conditions

- Flow rate is a critical factor in fire control, but a higher flow rate will not always provide more effective and efficient performance

- Low nozzle pressure provides less nozzle reaction but results in larger droplet size

- Higher nozzle pressure provides smaller droplet size but results in higher nozzle reaction

- Smaller droplets are more effective at cooling the hot gas layer

- Large droplets penetrate well and are effective at cooling hot surfaces

- Effective and efficient fire streams put water on target in the correct form and at an appropriate flow rate based on heat release rate of the fire

- Weight of the hoseline, flexibility, and nozzle reaction have significant impact on the effectiveness and efficiency of hoseline deployment.

Web Site Additions

CFBT-US has been working on a glossary of terms that are important to CFBT Instructors and other students of fire behavior. This is a work in progress, but have a look and feel free to provide your input or feedback on what we have accomplished so far. A link to the is provided on the CFBT-US Resources page.

In addition to the glossary, a link to the Fire Behavior Indicators Concept Map (version 5.2.1) has also been posted on the CFBT-US Resources” page.

Ed Hartin, MS, EFO, MIFireE, CFO

July 12th, 2014 at 10:41

I don’t know how old this post is, found it on a search.

Constant Volume nozzles also have a high-pressure moment: The engine pressure is set to overcome the friction loss while flowing. While the nozzle is closed, and for a split second after it is opened, the full engine pressure (less head loss) is experienced at the playpipe. This increased pressure lasts as long as it takes to achieve full flow rates and release some expansion of hose.

This may be an additional factor in HP tactics, as the small lines used introduce relatively large friction losses relative to nozzle pressure.